The Tasiast mine is one of the most prominent mineral projects in West Africa. Located in the sparsely populated, arid regions of northwestern Mauritania, it has grown from an exploration camp into a large-scale open-pit operation that shapes local economies, national export profiles and regional infrastructure. This article explores where the mine is located, what is extracted there, its economic importance for Mauritania, and several notable technical, social and environmental aspects that make the project interesting.

Location and setting

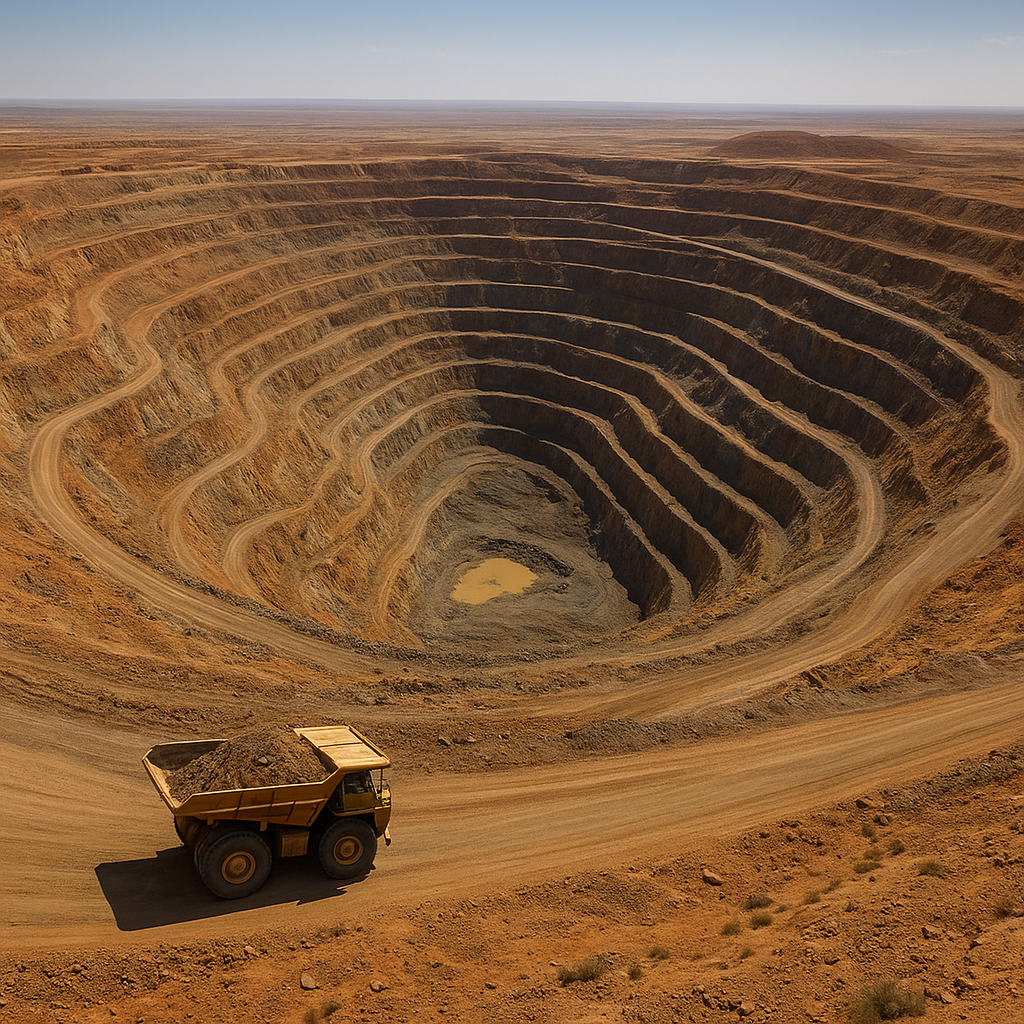

The Tasiast operation sits in the Saharan landscape of northwestern Mauritania, within a belt of ancient rocks that host precious metals across West Africa. The mine is remote: the nearest major urban centers are hundreds of kilometers away and travel involves long desert roads and, in some cases, air transport. Its position in a hot, dry climate with scarce freshwater resources and limited grid power underscores many of the operational choices made by the companies running the site.

The regional setting is characterised by broad plains, occasional rock outcrops and sand-covered terrain. Logistic routes linking the mine to ports for export are essential: maritime access allows gold concentrate and refined bullion to reach international markets and import fuel, reagents and parts necessary for continuous operation. The presence of a mine in such an environment has required investments in roads, power generation and housing for a largely fly-in fly-out workforce.

Geology, mineralisation and what is extracted

Tasiast is primarily a gold mine. The deposit typifies many large West African gold systems: gold occurs in both near-surface oxide ores, which are relatively straightforward to leach, and in deeper sulphide-bearing material requiring more complex processing. The mineralisation includes disseminated and structurally controlled veins, which have been delineated through systematic drilling campaigns over decades.

Ore types and processing

Early production at the site exploited oxide ores amenable to heap leach and conventional carbon-in-leach (CIL) processing, but as the operation matured it incorporated crushing, grinding and more intensive processing circuits to treat lower-grade and sulphide-bearing ore. This progression enabled the mine to increase throughput and recoveries. The combination of open-pit mining methods and on-site processing provides a vertically integrated operation, from extraction to doré production.

Exploration and resource definition

Extensive drilling and geological mapping have expanded the known resource base over time. Exploration programs at Tasiast have focused on both infill drilling to upgrade resources and regional exploration to discover satellite deposits around the central pit. These activities underpin the mine planning process and drive decisions on expansion phases and capital allocation.

History, ownership and development phases

The site moved from early-stage exploration to commercial production across several company ownerships and technical phases. International junior companies and larger producers contributed capital and expertise at different stages. Over the years there have been multiple development phases—each aiming to expand processing capacity, improve recoveries and extend the mine life through discovery and resource conversion.

Expansion programs have typically focused on increasing plant throughput, optimising ore handling and improving water and reagent use efficiency. Such projects often require substantial upfront investment but lead to lower unit costs and higher annual production, which is central to project economics in regions where operating and logistical costs are elevated by remoteness.

Economic significance for Mauritania

Tasiast is a leading contributor to Mauritania’s mining sector and national economy. Revenue streams from the mine include royalties, corporate taxes, infrastructure investments and local procurement. Gold sales contribute foreign exchange earnings that help stabilise public finances and enable imports of goods and services. For a country with limited economic diversification, a large-scale mineral operation is a major component of the export basket.

Beyond direct government receipts, the project generates employment—both directly at the mine and indirectly through service companies, contractors and local suppliers. Skilled positions often combine expatriate experts and trained Mauritanian staff, while unskilled and semi-skilled local labour is sourced from surrounding communities where possible. The mine’s demand for goods and services creates market opportunities for local entrepreneurs and boosts activity in regional centres.

Infrastructure and regional development

Investments tied to the mine have spillover benefits: upgraded roads, expanded telecommunications and power solutions deployed for the site can also serve surrounding communities. Companies involved in the operation frequently invest in community projects—clinics, schools and small-scale water systems—that complement public services. These initiatives, when well-aligned with local needs, help distribute benefits beyond payrolls and taxes.

Employment, social programs and community relations

Creating sustainable local employment remains a central objective. Training and capacity-building programs aim to increase the share of Mauritanian nationals in operational and management roles. The mine’s human resources policies typically combine workforce development with safety and occupational health programs tailored to the harsh desert environment.

Community engagement is another pillar of long-term social licence to operate. Companies maintain stakeholder relations offices, negotiate community development agreements, and engage local leaders to address grievances. Land access, compensation for disruptions and livelihood restoration are common topics. In many cases, mines implement small-business development schemes to help local suppliers meet the standards required for contracting with a modern mining operation.

Environmental management and sustainability efforts

Operating in an arid landscape necessitates careful stewardship of scarce natural resources. Water management is critical: processing plants and dust suppression systems must be balanced against limited groundwater and surface resources. Tailings and waste rock management are central concerns, and modern practice calls for engineered storage facilities, seepage control and progressive rehabilitation.

To mitigate greenhouse gas emissions and reduce dependence on diesel generation, the project has explored integration of renewable energy and energy efficiency measures. Such initiatives align with broader corporate and national sustainability goals. Biodiversity impacts are generally limited given the sparse desert ecology, but protecting delicate habitats and cultural sites remains part of environmental planning.

Regulatory compliance and monitoring

Environmental and social performance is governed by a mix of national regulation and international standards applied by financiers and investors. Continuous monitoring, third-party audits and reporting frameworks aim to ensure compliance and transparency. The mine’s ability to meet both legal obligations and stakeholder expectations influences its reputation and operational continuity.

Infrastructure, logistics and technical challenges

Remoteness imposes logistical complexity. Fuel, spare parts and consumables must travel long distances; disruptions to transport or supply chains can have outsized operational impacts. On-site power generation facilities, often running on heavy fuel oil or diesel, are essential but contribute to operating costs and emissions. Water supply systems typically combine local sourcing and recycling to minimise environmental footprint.

Seasonal weather extremes—intense heat, occasional sandstorms—affect equipment wear, worker safety and maintenance schedules. Designing facilities to withstand desert conditions has technological and cost implications, from material selection to cooling systems for critical equipment.

Technical innovation and processing improvements

Mines like Tasiast continuously evaluate metallurgical options to increase gold recovery and reduce costs. Advances in comminution, mineral liberation, leaching chemistry and carbon handling can materially improve economics. Automation, remote monitoring and digital process control also enhance plant reliability and optimisation, allowing operators to maintain high throughput with reduced downtime.

Research into low-cost tailings reprocessing and recovery of secondary metals can extend value extraction from existing stockpiles. Such innovations also support environmental goals by reducing the volume of material destined for disposal.

Challenges, risks and governance

Key risks include commodity price volatility, which directly affects project revenues and investment decisions. Political and regulatory stability, local community relations and security in remote areas also shape project risk profiles. Effective governance—transparent contracts, clear revenue-sharing mechanisms and strong environmental oversight—helps mitigate these risks and build long-term value for the host country.

Corruption risks and the equitable distribution of mining rents are recurring governance themes in resource-rich countries. Strengthening institutions and ensuring that mining revenue funds sustainable development priorities are long-term challenges for Mauritania and other mining jurisdictions.

Future prospects and strategic considerations

The future of the Tasiast project depends on continued exploration success, operational efficiency and the ability to adapt to evolving environmental and social expectations. Potential avenues for growth include discovering satellite deposits, increasing plant throughput, and incorporating new processing technologies to treat refractory ore. Each of these options requires capital investment and careful planning to balance short-term returns with long-term sustainability.

From a national perspective, ensuring that the economic benefits of the mine are channeled into diversification, education and infrastructure can reduce reliance on a single commodity and spread prosperity more widely. For operators, the focus will remain on optimising costs, reducing energy intensity and maintaining strong community partnerships to secure the social licence to operate.

Interesting facts and notable features

- The mine operates in one of the planet’s harshest climates, which influences everything from workforce rotation to equipment design and water management.

- The project evolved from modest exploration to a large-scale operation through successive expansion phases, illustrating how incremental investment and sustained exploration can transform a deposit’s value.

- Many modern large open-pit gold operations, including this one, treat both oxide and sulphide ores, requiring flexible processing circuits that can adapt as the ore body changes with depth.

- Because of the logistical challenges, the site is an example of how mining can drive infrastructure development in remote regions, providing roads and services that benefit local communities.

- The operation has increasingly focused on energy efficiency and reductions in fuel use—trends that reflect broader industry pressures to lower carbon footprints and operating costs.

Conclusion

The Tasiast mine stands as a significant economic asset in northwestern Mauritania, extracting valuable gold from challenging terrain and supporting national export earnings while shaping local development. Its evolution from exploration to full-scale production highlights the technical ingenuity and substantial capital needed to operate successfully in remote desert settings. Balancing the opportunities from resource extraction with responsible environmental management and equitable social outcomes will define the mine’s legacy and its contribution to Mauritania’s future.