The Sishen Mine, set amid the red sands of South Africa’s interior, is one of the country’s most prominent mineral assets. Its vast open pit, industrial infrastructure and long transportation corridor to the Atlantic seaboard make it a cornerstone of the regional economy and a key component of the global iron ore supply chain. This article examines the mine’s location and geology, its operations and products, its wider economic significance, and a selection of interesting or lesser-known aspects that highlight why Sishen matters beyond the obvious metrics of tonnage and revenue.

Location and geological setting

Sishen is located in the arid landscape of the Northern Cape province, roughly adjacent to the town of Kathu in the Kalahari region. The area is characterised by flat expanses, sparse vegetation and striking red soils — features that make large-scale surface mining both practicable and highly visible. The mine lies within a broader iron-rich geological province that hosts several significant iron ore deposits across South Africa.

Geological character

The deposit mined at Sishen is a classic iron ore body dominated by high-grade hematite and magnetite mineralisation. These rocks formed in ancient sedimentary and chemical processes that concentrated iron in extensive beds and layers. Because of the relatively high iron content and favourable ore characteristics, the material at Sishen can be treated and shipped as direct shipping ore after appropriate crushing and screening, or further processed by beneficiation to produce standardized products for industrial steelmaking.

Strategic setting

Geographically and logistically, Sishen occupies a position that links inland mineral wealth with coastal export capability. The distance from mine to port is a defining feature of operations and planning: ore must be moved efficiently across hundreds of kilometres of sparsely populated terrain to reach export facilities on the Atlantic coast. That corridor has driven an associated investment in heavy-haul rail and port infrastructure that serves both the mine and the wider South African mineral export industry.

Mining operations and products

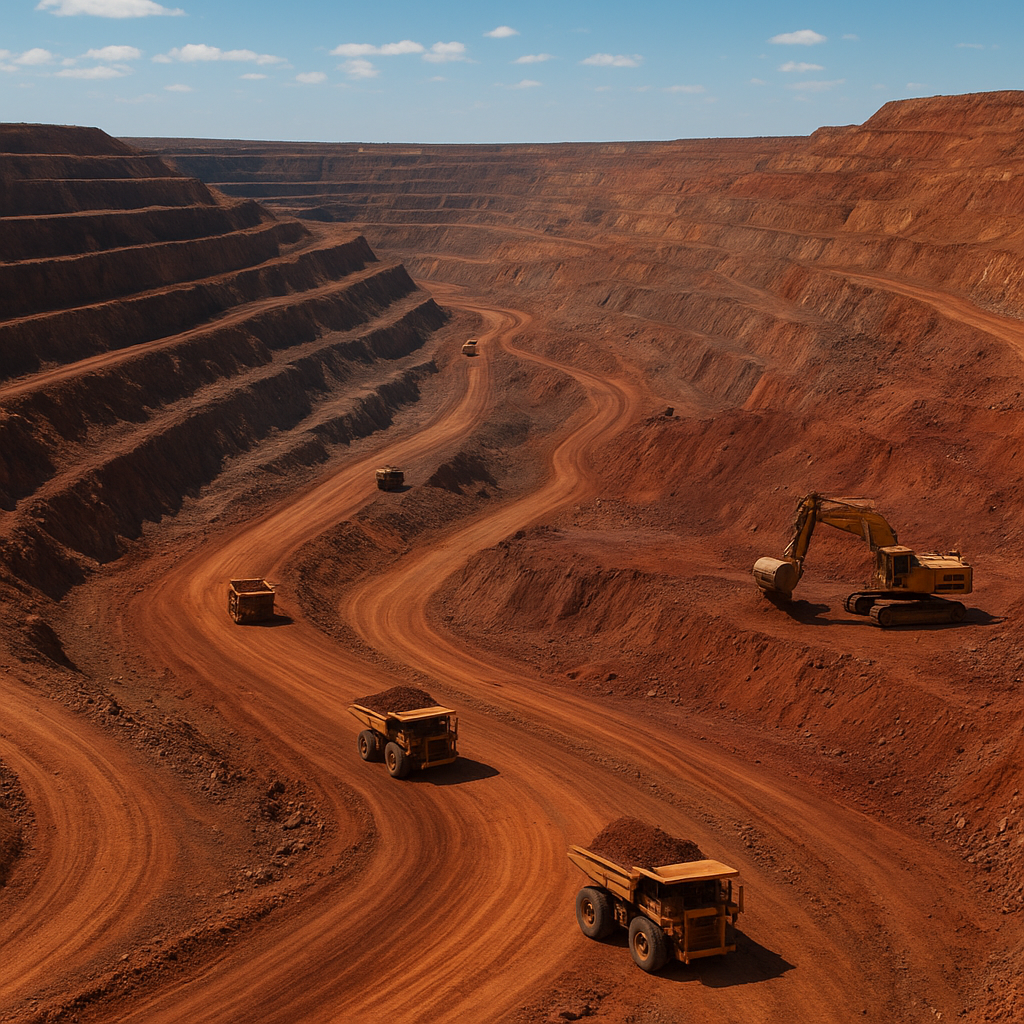

Sishen is principally an open-pit iron ore mine, where operations involve large-scale surface excavation, removal of overburden, and staged extraction of ore benches. Over the decades of operation, the pit has grown into one of the largest mining excavations in Africa, shaped by blast cycles, heavy mobile equipment and sophisticated ore handling systems.

Extraction and processing

Mining at Sishen follows a typical cycle of drilling, blasting, loading and haulage using large shovels and trucks. Once ore is extracted, it is processed in a complex that includes crushing, screening and washing plants. The objective of processing is to produce marketable products: iron ore in the form of lump and fines suitable for blast furnace feed or sinter plants. Some material, depending on its grade and metallurgical qualities, undergoes further beneficiation to meet strict customer specifications.

- Primary products: lump ore and sinter fines

- Processing steps: crushing, screening, washing, blending

- Quality control: sampling and laboratory analysis to ensure consistent grades

Logistics and transport

Moving millions of tonnes of ore annually from a remote mine to ocean-going vessels is a logistical challenge that Sishen solved by integrating mine operations with heavy-haul rail and port facilities. The mine relies on a dedicated rail corridor to the port of Saldanha Bay, enabling large-scale export volumes. Rail operations are a central part of the mine’s supply chain, with trains of considerable length and mass moving ore continuously. At the port, ore is stockpiled, blended and loaded onto bulk carriers for international customers.

Economic importance and regional impact

Sishen’s role in the local and national economy extends well beyond direct mineral revenues. Its presence has shaped employment patterns, urban development, transport networks and fiscal contributions through taxes, royalties and local procurement.

Employment and community

The mine and its associated operations provide direct and indirect employment to thousands of people. Direct jobs include roles in mining, processing, maintenance, rail logistics and management. Indirect employment arises in services, supply chains, construction and local commerce. The nearby town of Kathu developed in many ways as a service and residential hub for mine employees and their families, with schools, healthcare facilities and housing evolving in tandem with the mine’s growth.

Revenue, exports and national significance

Sishen contributes significantly to South Africa’s mineral exports. Iron ore is one of the country’s major bulk commodity exports, and mines like Sishen supply large industrial customers around the world. Revenues from ore sales translate into export earnings, foreign exchange inflows and government revenues through corporate taxes and royalties. These links make Sishen not only a local employer, but also an integral part of national economic strategy for mineral-driven growth.

Infrastructure multiplier effects

Investment in ore transport and port capacity at Sishen has wider benefits: improved rail corridors, power supply upgrades, and port handling capacity all support other sectors of the economy. The heavy-haul railway that connects the mine to the coast is a lasting piece of strategic infrastructure that reduces transport costs for bulk materials and promotes industrial competitiveness across the region. Such upgraded infrastructure also attracts ancillary investors and enables new economic activities, helping to diversify the local economy over time.

Environmental and social considerations

Large-scale open-pit mining inevitably raises environmental and social challenges that require careful management. In an arid region like the Kalahari, water management, dust control and land rehabilitation are of particular importance.

Water and dust

Water is a scarce resource in the Northern Cape. Mining activities demand water for processing, dust suppression and domestic use in mining towns. Responsible operations balance process requirements with conservation measures, wastewater treatment and reuse initiatives. Dust from crushing, stockpiling and hauling can affect air quality and local vegetation; hence, mitigation measures such as covered conveyors, water sprays and vegetative barriers are commonly deployed.

Rehabilitation and land use

As the mine progresses through stages of extraction, operators plan for post-mining landforms, progressive rehabilitation and safe closure. Rehabilitation includes reshaping waste dumps, replacing topsoil where possible, and selecting vegetation suited to local climatic conditions. Because the mine alters landscapes at a large scale, planning for long-term stability and post-mining land use is an ongoing responsibility.

Social licence and community investment

Maintaining a social licence to operate requires constructive engagement with communities, meaningful local procurement, training and skills development programs, and support for local infrastructure such as schools and clinics. Many mines run community development initiatives that focus on education, entrepreneurship and healthcare to build resilient local economies and reduce dependence on a single employer over time.

Historical background and corporate context

Sishen’s history stretches back decades and reflects broader shifts in South Africa’s mining sector and global iron ore markets. Over time, investment cycles, ownership structures and market demands have shaped how the mine is operated and expanded.

From discovery to large-scale production

Exploration in the iron-rich belts of the Northern Cape led to the development of substantial surface mines. Sishen was established to leverage a particularly rich ore body and to build export capacity in concert with national rail and port systems. The mine’s growth followed the global rise in steel demand and industrialisation in emerging economies, prompting expansions in pit size, processing capacity and logistics throughput.

Corporate players and partnerships

Operators and stakeholders at Sishen have included major South African mining companies and international partners. Corporate strategies have combined capital investment, technical expertise and local engagement to maximise resource value while navigating regulatory, environmental and social obligations. Over time, joint ventures, off-take agreements and market partnerships have ensured a steady flow of ore to global customers.

Interesting facts and lesser-known features

Sishen has traits and stories that go beyond production figures, reflecting both the scale of the operation and its cultural and technical significance.

- Huge pit visibility: The size of the open pit makes it visible from afar and even discernible in satellite imagery, providing a stark example of human alteration of landscape at industrial scale.

- Heavy-haul rail engineering: The rail link to Saldanha Bay includes heavy-duty tracks and powerful locomotives built for continuous, high-tonnage movements. In aggregate, the trains on that corridor represent one of the most intensive bulk-rail operations in Africa.

- Economic lifeline: For towns like Kathu, the mine is not merely an employer but a driver of local services, education and healthcare infrastructure. The mine’s activities have helped turn a remote area into a regional hub.

- Technological evolution: Over time, Sishen has incorporated newer processing technologies and automation to improve efficiency and safety, a trend mirrored in other large-scale mines globally.

- Global linkages: Ore from Sishen enters global steelmaking value chains, connecting a remote Kalahari operation with manufacturing centres in Asia, Europe and beyond.

Challenges and future outlook

Sishen faces both cyclical market pressures and long-term operational challenges that will shape its trajectory. Global iron ore prices, shifts in demand driven by construction and manufacturing, and competition from other resource jurisdictions influence planning horizons. Operationally, the mine must manage declining ore grades in some zones, extend life-of-mine through exploration and resource conversion, and invest in technologies that reduce environmental footprints.

Opportunities for extension and value capture

Opportunities to extend the mine’s commercial life include infill drilling to convert inferred resources, improvements to processing to upgrade lower-grade material, and value-added strategies such as downstream beneficiation or strategic marketing to niche steelmakers. Partnerships and investments in rail and port capacity can unlock greater export potential and reduce per-tonne logistic costs.

Balancing sustainability and profitability

Increasingly, investors and regulators expect mining companies to align profitability with sustainability. For Sishen this means pursuing energy efficiency, reducing greenhouse gas emissions where possible, improving water stewardship, and deepening engagement with communities so that benefits are shared and sustained. Successfully balancing these demands will be critical to the mine’s social licence and long-term commercial viability.

Key takeaways about Sishen’s role

As a prominent iron ore operation in the Northern Cape, Sishen exemplifies how a single resource asset can drive regional transformation. Its extraction of high-quality iron ore, operation under a major mining company such as Kumba Iron Ore, use of dedicated heavy-haul logistics including the Sishen–Saldanha rail link, and its socioeconomic footprint in terms of employment and regional infrastructure investments all underline the mine’s multifaceted importance. While the site faces environmental and market-related challenges, its established infrastructure and geological endowment give it enduring strategic value.