The Roy Hill Mine is a striking example of a modern, large-scale resource development in Western Australia. Located in the heart of the Pilbara region, it stands as one of the significant producers of iron ore in the world. This article explores where the mine is situated, what it produces, its broader economic role, and several engaging facts about its development, operation and impact on local communities and global markets.

Geographic setting and geology

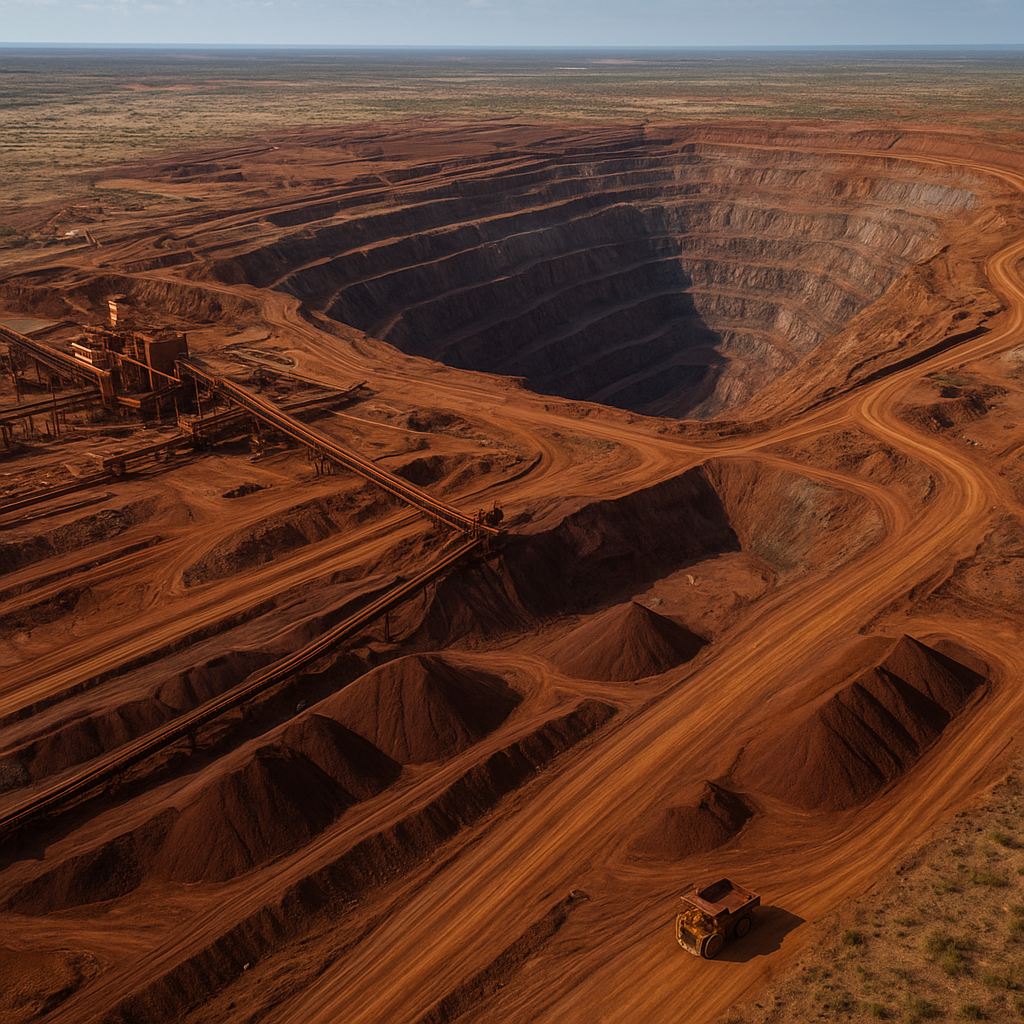

The mine sits in remote northwestern Western Australia, embedded in the mineral-rich landscape of the Pilbara. The site is associated with ancient banded iron formations that have given the region its extraordinary concentration of high-quality ore. The terrain is characterized by arid plains, scattered ranges, and sparse vegetation, conditions that pose both logistical and environmental management challenges for any large industrial project.

Roy Hill is a greenfield project developed on land historically known as Roy Hill Station. Its location was chosen for the presence of extensive ironbearing ore bodies that are amenable to open-pit mining. The ore typically consists of both lump and fines, which are the two primary marketable product types in the iron ore industry. Production focuses on beneficiating and blending ore to meet market specifications for steel mills, particularly those in East Asia.

Operations: what is mined and how

At its core, Roy Hill extracts high-grade iron ore through conventional open-pit mining methods. After removal of overburden, large-scale drilling, blasting, and hauling operations bring ore to primary crushing and screening facilities. The material is processed to separate lump and fines fractions and to reduce impurities to meet contractual quality standards.

Production capacity and products

The operation was developed to a nameplate capacity of around 55 million tonnes per annum in its initial phase, designed to supply both lump and fines to international markets. The product range is tailored for steelmakers requiring consistent grade and chemistry. Through stockyard management and blending, Roy Hill can deliver tailored shipments that match buyer specifications, securing premium prices for higher-grade material.

Processing and technology

Processing at Roy Hill integrates heavy earthmoving fleets, primary crushers, screening and material handling systems, including large stacker-reclaimer units at the port. The project incorporated modern control systems and digital monitoring from its inception, and operations emphasize efficiency to reduce unit costs. While the Pilbara’s larger miners have advanced automation on rail and haulage, Roy Hill combines robust fleet operations with evolving technology to maximize throughput and reliability.

Infrastructure and logistics

Moving iron ore from a remote mine to global customers necessitates a comprehensive logistical chain. Roy Hill invested in an integrated infrastructure network that connects the mine to a purpose-built export facility.

- Railway: A dedicated heavy-haul railway links the mine site with the export terminal. The rail line is engineered to handle high axle loads and frequent train movements, enabling the continuous flow of millions of tonnes per year.

- Port Hedland: Roy Hill exports via facilities at Port Hedland, one of the world’s busiest bulk commodity ports. The port infrastructure includes ship loaders, berths, and conveyors capable of staging and loading very large ore carriers efficiently.

- Road and onsite logistics: Extensive haul roads, workshops, power generation, and water supply systems were constructed to support round-the-clock mining. These onsite networks are essential for operational resilience in an isolated environment.

Developing this integrated network required coordination across engineering, maritime, rail, and supply-chain disciplines, as well as significant capital investment. The creation of rail and port links turned Roy Hill from an isolated deposit into a global exporter.

Economic significance

The Roy Hill project is a major contributor to the regional and national economy. It represents a multi-billion dollar investment with long-term export flows that generate revenue, government royalties, and local economic activity.

- Exports: Roy Hill’s production is primarily destined for export markets, notably steel producers in Asia, which makes the mine an important player in global iron ore exports.

- Revenue and fiscal impacts: The sale of ore brings significant export earnings to Australia, supporting national accounts and contributing to Western Australia’s treasury through taxes and royalties.

- Local economies: Construction and operational phases inject money into local economies through procurement, accommodation, and service contracts. Towns such as Newman and Port Hedland benefit from increased demand for goods and services.

- Employment: The project created thousands of roles during construction and supported a substantial roster of ongoing positions for operations and maintenance, supply chain, and management. Roy Hill’s employment footprint includes direct employees, contractors, and associated suppliers.

Beyond immediate finances, Roy Hill helps to diversify the ownership and export base of Australia’s mining sector. It strengthens the Pilbara’s profile as a dependable supplier of high-quality iron ore, which underpins long-term trade relationships with importing countries.

Social and environmental considerations

Large-scale mining projects in remote regions inevitably raise social and environmental questions. Roy Hill has engaged in a range of measures to manage impacts, meet regulatory obligations and build relationships with Traditional Owners.

- Indigenous engagement: The project negotiated agreements and partnerships with local Indigenous groups, covering employment, cultural heritage protection, and business opportunities. These arrangements aim to provide tangible benefits to communities while protecting sacred sites and cultural values.

- Rehabilitation and biodiversity: Roy Hill’s environmental programs address progressive rehabilitation of disturbed land, water management in an arid region, and minimization of dust and noise. The mine must comply with strict environmental approvals that set standards for biodiversity conservation and postmining landforms.

- Resource efficiency and sustainability: Operators invest in initiatives to reduce water consumption, improve energy efficiency, and lower greenhouse gas emissions per tonne of ore produced. While mining is inherently resource intensive, continuous improvement efforts target more sustainable practices and reporting on environmental performance.

Interesting and notable aspects

Several features of Roy Hill make it interesting beyond its commercial role. The project is a modern greenfield development built to global standards and designed for high-volume, long-life production. A few notable points include:

- Scale and speed: Developing a major mine, railway, and port facilities in a relatively compressed timeframe required extraordinary logistical coordination and a large construction workforce. The scale of simultaneous civil, mechanical, and marine works set it apart from many expansions of existing operations.

- Integrated design: Roy Hill was conceived as an integrated export supply chain from the outset. Owning or controlling the mine-to-port route reduces reliance on third-party infrastructure and enables tighter control over scheduling and product quality.

- Market timing: Roy Hill began shipping ore in the mid-2010s when global iron ore demand was strong. Its entry into the market added supply that supported long-term contracts with major steel producers.

- Workforce and fly-in fly-out culture: Given the remote location, much of the workforce operates on a fly-in fly-out roster, raising operational and social dynamics around worker wellbeing, community engagement and regional service provision.

Challenges and future outlook

The future for Roy Hill is shaped by commodity cycles, technological change, and shifting expectations around environmental performance. Key themes include:

- Market volatility: Iron ore prices can be volatile, influenced by global steel demand, supply dynamics, and macroeconomic conditions. Long-term contracts help stabilize revenues, but market exposure remains.

- Operational efficiency: Continuous improvement in throughput, cost control and reliability is critical to remain competitive. Investments in predictive maintenance, digital operations and optimized logistics are ongoing priorities.

- Decarbonisation pressures: As steelmakers and governments seek lower-carbon supply chains, miners face increasing pressure to reduce Scope 1 and Scope 2 emissions. Initiatives might include electrification of equipment, renewable energy for camp and processing power, and more efficient material handling.

- Community expectations: Engagement with Indigenous groups, local businesses, and regional workers will continue to be central, ensuring that social benefits are enduring and cultural heritage is respected.

Concluding observations

Roy Hill stands as a contemporary example of how large-scale mining projects are conceived and executed in Australia. Its combination of remote-location engineering, integrated logistics, and market-facing production underscores the complexity and influence of modern resource projects. The mine’s contributions to regional employment, national exports and global steelmaking chains are significant, while its ongoing challenges highlight the evolving balance between resource development, community interests and environmental stewardship.