Rare Earth Elements (REEs) are a group of seventeen chemical elements in the periodic table that are critical to the manufacturing of a wide range of consumer electronics. Despite their name, most of these elements are relatively abundant in the Earth’s crust, but their economic extraction and processing present significant challenges. This article provides an overview of the role of rare earth elements in consumer electronics, highlighting their applications, the challenges associated with their supply, and the ongoing efforts to mitigate these issues.

The Critical Role of REEs in Consumer Electronics

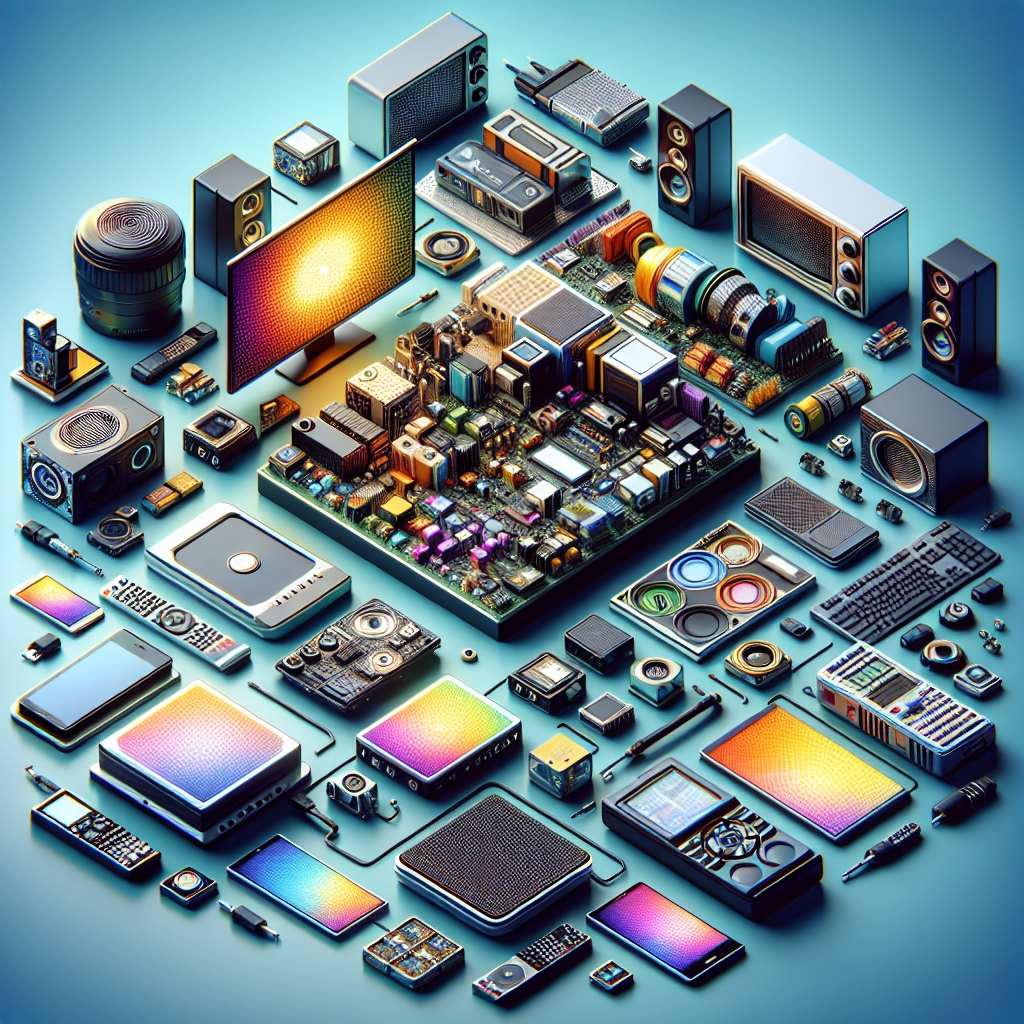

Rare earth elements, including neodymium, dysprosium, terbium, europium, and yttrium, among others, are essential for the production of high-performance magnets, phosphors, and other components used in a wide array of consumer electronics. These elements are key to the functionality and efficiency of products ranging from smartphones, laptops, and tablets to cameras, flat-screen TVs, and LED lights.

For instance, neodymium is a critical component in the powerful magnets used in headphones, speakers, and hard disk drives. Dysprosium and terbium are added to neodymium magnets to maintain their performance at high temperatures, which is crucial for the motors in electric vehicles and wind turbines. Europium and yttrium are used to produce the vibrant colors seen on smartphone and television screens. The unique properties of REEs, such as their magnetic, luminescent, and electrochemical capabilities, make them irreplaceable in many applications.

Supply Challenges and Environmental Concerns

The supply of rare earth elements is concentrated in a few countries, with China dominating the market. This concentration poses significant risks to the global supply chain, including political instability, trade restrictions, and fluctuating prices. The extraction and processing of REEs are also associated with substantial environmental and health risks, including the production of toxic waste and significant carbon emissions.

Mining operations for rare earth elements often lead to habitat destruction, water pollution, and soil contamination. The refining process is chemically intensive, requiring large amounts of acid and generating hazardous waste. These environmental challenges have led to strict regulations in some countries, further complicating the supply situation.

Efforts to Mitigate Supply Risks

In response to these challenges, there are ongoing efforts to diversify the supply of rare earth elements and reduce dependence on single sources. Countries and companies are investing in the exploration and development of new mines in regions such as Australia, Canada, and parts of Africa. Recycling initiatives for consumer electronics are also gaining traction as a means to recover rare earth elements, although current technologies for recycling REEs are still in the early stages and not yet widely implemented.

Research and development are focused on finding alternative materials that can replace rare earth elements in certain applications. While some progress has been made, replicating the unique properties of REEs has proven difficult. Nonetheless, advancements in material science and nanotechnology hold promise for the development of substitutes or more efficient use of rare earth elements in consumer electronics.

In conclusion, rare earth elements play a pivotal role in the functionality and efficiency of consumer electronics. However, the challenges associated with their supply and environmental impact necessitate a multifaceted approach to ensure their sustainable use. Through diversification of supply sources, recycling, and the development of alternative materials, the electronics industry can mitigate these risks and continue to innovate while reducing its environmental footprint.