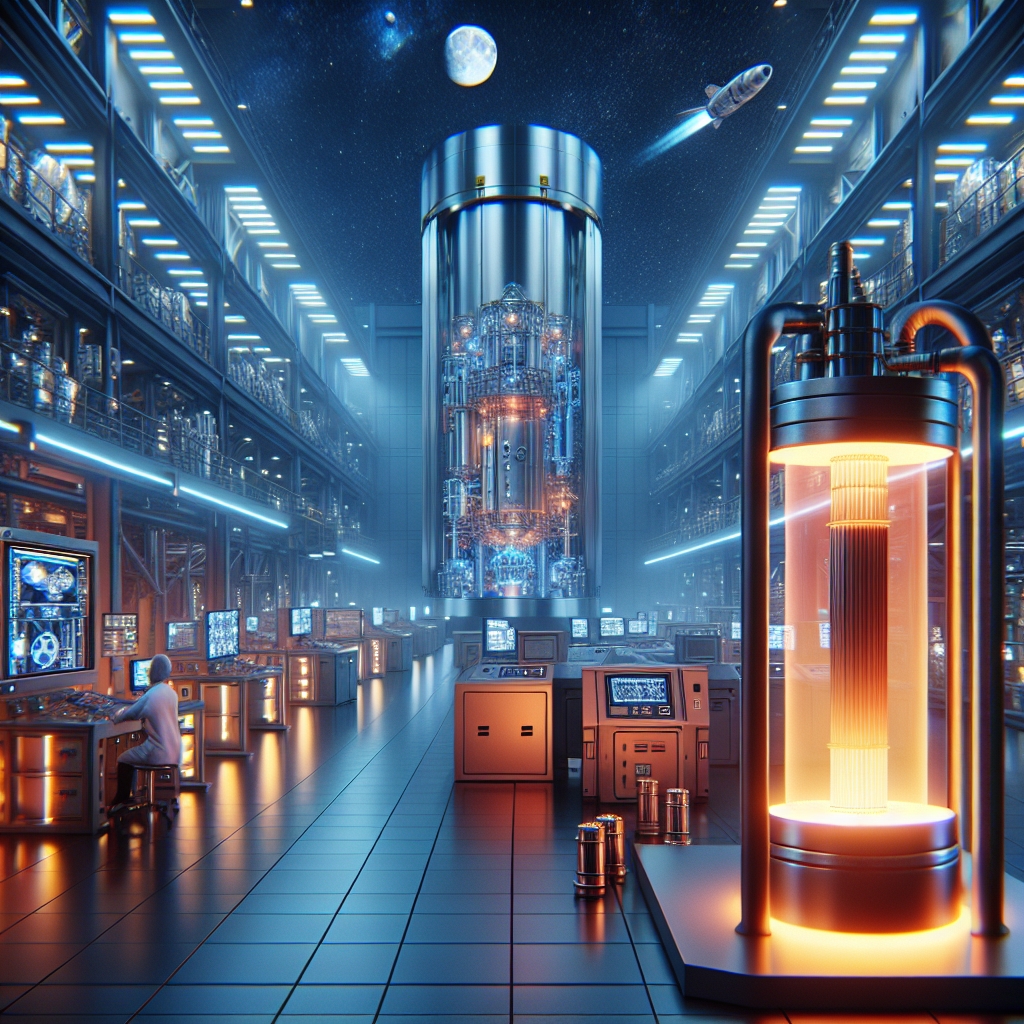

Rare Earth Elements (REEs) have become indispensable in the field of aerospace technology, powering innovations and enhancing the performance of various aerospace components. These elements, often hidden in plain sight within the devices and machinery that define modern aviation and space exploration, play pivotal roles in the advancement of this high-stakes industry. This article delves into the significance of REEs in aerospace technology, exploring their applications, challenges associated with their use, and the future prospects of these critical materials in the aerospace sector.

The Role of Rare Earth Elements in Aerospace Technology

Rare Earth Elements, a group of seventeen elements including scandium, yttrium, and the fifteen lanthanides, are prized for their unique magnetic, luminescent, and electrochemical properties. In the aerospace industry, these properties translate into critical functionalities that cannot be easily replicated by other materials. For instance, neodymium, one of the most well-known REEs, is used to make powerful permanent magnets that are essential in the motors of electrically powered aircraft. Similarly, europium and terbium are used in fluorescent lighting systems, while erbium-doped fiber amplifiers are vital in laser communications systems, a technology increasingly employed in satellite communications.

One of the most significant applications of REEs in aerospace technology is in the manufacturing of high-performance alloys. Scandium, for example, is added to aluminum to create materials that are lightweight yet strong, significantly enhancing the fuel efficiency of aircraft. These scandium-aluminum alloys are not only used in the structure of the aircraft but also in components like the landing gear, where strength and resilience are paramount. Furthermore, the thermal resistance properties of certain REEs are critical in the production of aerospace engines, where materials must withstand extremely high temperatures.

Challenges and Solutions in the Use of Rare Earth Elements

Despite their invaluable contributions to aerospace technology, the use of REEs comes with its set of challenges. The extraction and processing of REEs are environmentally damaging, often involving toxic chemicals and generating hazardous waste. Moreover, the supply chain of REEs is geopolitically sensitive, with a significant portion of the world’s supply coming from a limited number of countries, leading to potential vulnerabilities in the aerospace industry’s supply chain.

To mitigate these challenges, the aerospace industry, along with governmental and research institutions, is actively seeking alternatives and solutions. Recycling of REEs from end-of-life products and the development of more sustainable extraction methods are among the strategies being explored. Additionally, research into alternative materials that can replicate or even surpass the properties of REEs is ongoing. For instance, scientists are investigating the potential of using nanomaterials and other advanced materials as substitutes for REEs in certain applications.

Future Prospects of Rare Earth Elements in Aerospace

The future of REEs in aerospace technology looks promising but is contingent upon overcoming the current challenges related to their supply and environmental impact. Innovations in recycling and material science could play pivotal roles in ensuring the sustainable use of REEs. Moreover, as the aerospace industry continues to evolve, with a growing focus on sustainability and efficiency, the demand for REEs is likely to increase, given their critical role in enabling these advancements.

Furthermore, the exploration of space presents new opportunities for the use of REEs. The unique properties of these elements could be instrumental in the development of technologies for deep space exploration and habitation. For example, REEs could be used in the development of high-efficiency power systems and life support systems in spacecraft and extraterrestrial habitats.

In conclusion, Rare Earth Elements are at the heart of many technological advancements in aerospace technology, offering unique properties that are difficult to match. While their use presents significant challenges, ongoing research and innovation hold the key to overcoming these obstacles, ensuring that REEs continue to play a vital role in the aerospace industry’s future. As we look to the skies and beyond, the importance of these elements in pushing the boundaries of what is technologically possible cannot be understated.