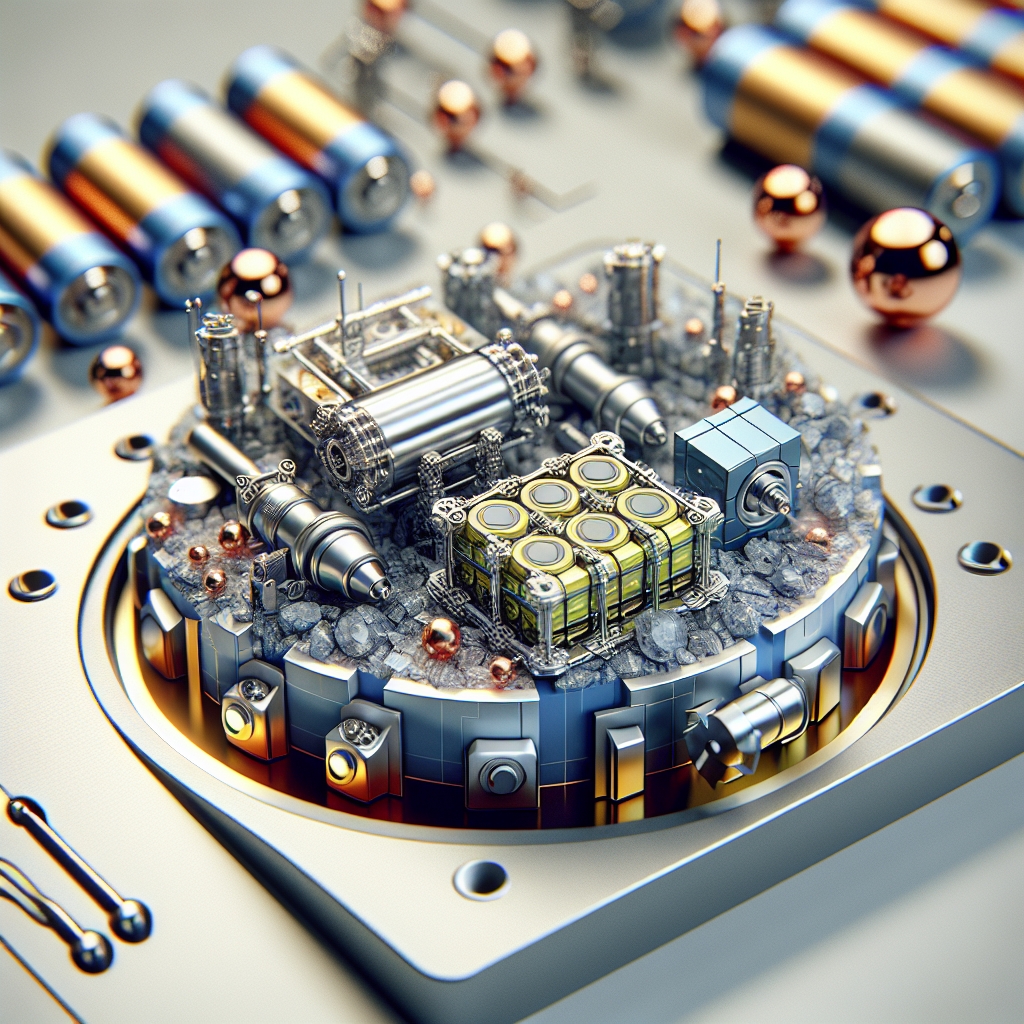

Rare Earth Elements (REEs) have become indispensable in the development of advanced battery technologies, powering everything from electric vehicles to renewable energy storage systems. These elements, often hidden in the periodic table’s lanthanide series, along with scandium and yttrium, are pivotal in enhancing battery performance, longevity, and efficiency. This article delves into the role of REEs in battery technology, exploring their applications, challenges, and the future landscape of energy storage solutions.

The Critical Role of Rare Earth Elements in Battery Technology

The unique properties of rare earth elements, such as high magnetic strength, conductivity, and electrochemical capabilities, make them essential in the realm of advanced battery development. Specifically, elements like neodymium, dysprosium, and lanthanum are key components in the manufacture of high-performance batteries. For instance, neodymium is crucial for producing powerful magnets used in electric motors, while lanthanum is a major component in nickel-metal hydride (NiMH) batteries, which are prevalent in hybrid vehicles.

Moreover, the addition of rare earths to lithium-ion batteries can significantly improve their performance. Dysprosium, for example, can enhance the durability and thermal stability of lithium-ion batteries, making them safer and more reliable. This is particularly important in electric vehicles (EVs) and aerospace applications, where battery failure can have serious consequences. The inclusion of rare earth elements in battery electrodes and electrolytes also contributes to increased energy density, allowing for longer battery life and extended range for EVs.

Challenges and Environmental Considerations

Despite their benefits, the extraction and use of rare earth elements in battery technology pose several challenges. The mining of REEs is often associated with significant environmental damage, including soil and water pollution, and the production process can release harmful emissions. Moreover, the supply of rare earths is geopolitically sensitive, with a majority of the world’s reserves located in China. This concentration of supply raises concerns about market volatility, price manipulation, and the risk of supply disruptions.

Furthermore, the recycling of rare earth elements from used batteries remains technically challenging and economically unviable in many cases. The development of efficient recycling processes is crucial to mitigate the environmental impact of REE mining and to ensure a sustainable supply of these critical materials for future battery production.

Looking Towards the Future

As the demand for advanced batteries continues to grow, driven by the global push towards electrification and renewable energy, the role of rare earth elements in this sector is set to become even more significant. Researchers and companies are actively seeking ways to reduce the reliance on REEs, either by developing alternative materials with similar properties or by improving recycling technologies to recover rare earths from end-of-life batteries.

Innovations in battery technology, such as solid-state batteries, which promise higher energy densities and improved safety profiles, may also reduce the need for rare earths. However, until such technologies become commercially viable, REEs will remain a critical component of battery development. The challenge lies in balancing the demand for these materials with the need to address environmental and supply chain risks.

In conclusion, rare earth elements play a pivotal role in the advancement of battery technology, offering unique properties that enhance performance and efficiency. However, the environmental and geopolitical challenges associated with REEs necessitate a concerted effort to find sustainable solutions. Through innovation in materials science and improvements in recycling and extraction processes, the battery industry can continue to harness the benefits of rare earths while minimizing their impact on the planet and ensuring a stable supply for the future.