The quest for sustainability and environmental preservation has led to significant advancements in the recycling processes of rare earth elements (REEs). These elements, crucial for the manufacturing of high-tech devices, renewable energy technologies, and defense systems, are not only scarce but also pose considerable environmental challenges during their extraction and processing. Innovations in recycling methodologies are thus pivotal in mitigating these impacts, ensuring a steady supply of REEs, and promoting a circular economy. This article delves into the latest breakthroughs in the field of rare earth element recycling, exploring both the technological and economic aspects that drive their development.

Technological Advancements in REE Recycling

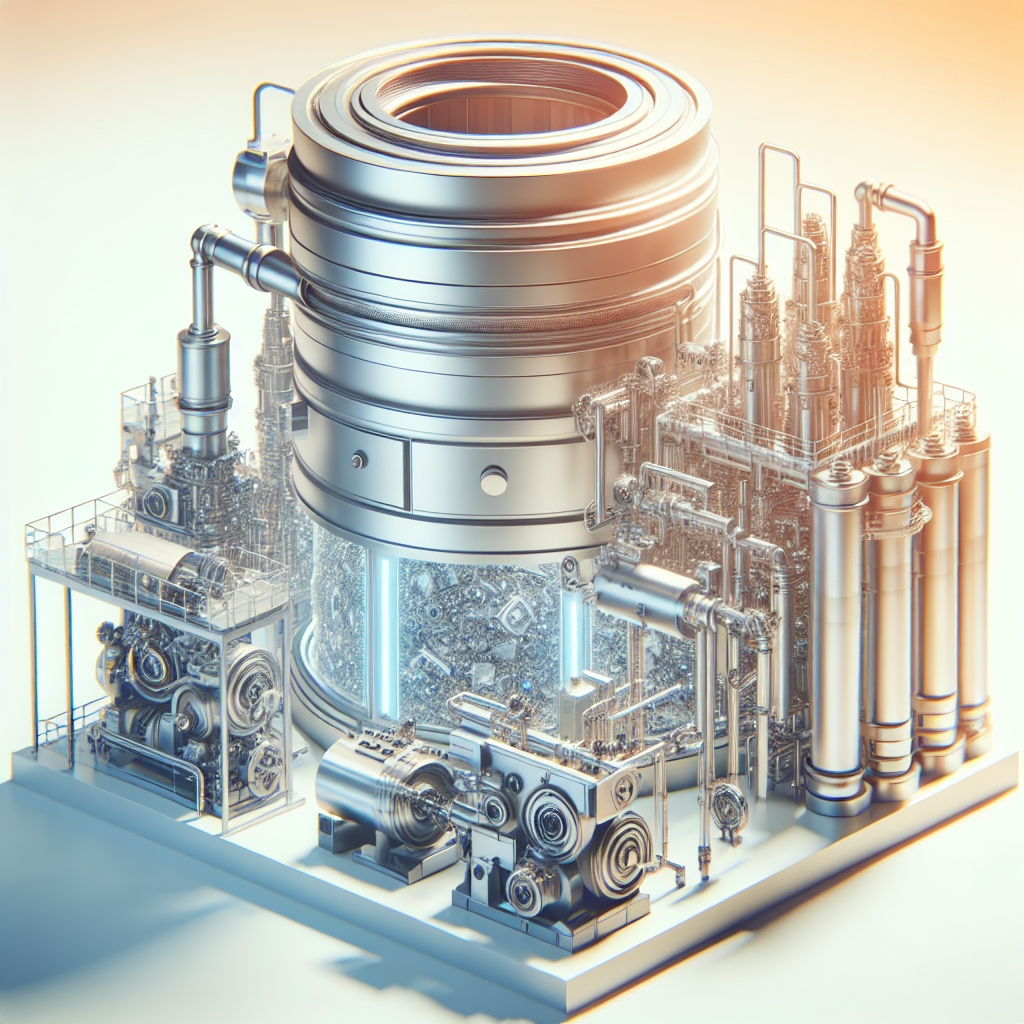

The recycling of rare earth elements has traditionally been challenging due to their dispersed usage in products and the complex separation processes required. However, recent technological innovations have begun to change this landscape. One of the most promising developments is the use of hydrometallurgical techniques, which involve the use of aqueous chemistry to recover REEs from various waste streams. These methods have shown potential in extracting REEs from discarded magnets, batteries, and other electronic waste with higher efficiency and lower environmental impact than conventional methods.

Another significant advancement is the application of bioleaching, where microorganisms are used to extract metals from solid materials. This method is particularly appealing due to its low energy requirements and minimal environmental footprint. Researchers have identified specific strains of bacteria that can efficiently leach rare earth elements from electronic waste, offering a greener alternative to traditional extraction techniques.

Electrochemical methods have also seen considerable progress. These involve the use of electrical currents to precipitate or dissolve metals, allowing for the selective recovery of REEs from mixed waste streams. Innovations in electrode design and electrolyte composition have improved the selectivity and efficiency of these processes, making them more viable for large-scale operations.

Economic and Environmental Implications

The economic viability of recycling rare earth elements is closely tied to the fluctuating prices of these metals on the global market. As demand for REEs continues to rise, driven by the expansion of green technologies and electronic devices, the economic case for recycling strengthens. The development of more efficient recycling processes can help stabilize supply chains and reduce dependency on primary sources, which are often located in geopolitically sensitive regions.

From an environmental perspective, the benefits of recycling REEs are manifold. By reducing the need for new mining operations, recycling can significantly lower the ecological footprint associated with REE production. This includes reductions in greenhouse gas emissions, water usage, and the release of toxic chemicals into the environment. Moreover, the advancement of cleaner recycling technologies further minimizes the environmental impact of these processes.

However, the transition to a more circular economy for rare earth elements also faces several challenges. These include the need for better collection and sorting systems for electronic waste, the development of economically viable recycling processes for low-concentration REE sources, and the creation of regulatory frameworks that support recycling initiatives. Overcoming these hurdles will require coordinated efforts from governments, industry, and research institutions.

Conclusion

The innovations in rare earth element recycling processes mark a significant step forward in the quest for sustainable resource management. By improving the efficiency and reducing the environmental impact of REE recovery, these advancements hold the promise of a more sustainable and secure supply of these critical materials. However, realizing the full potential of these technologies will require overcoming economic and logistical challenges, underscoring the need for continued investment in research and development. As the world moves towards a greener and more technologically advanced future, the role of rare earth recycling in achieving these goals becomes increasingly important.