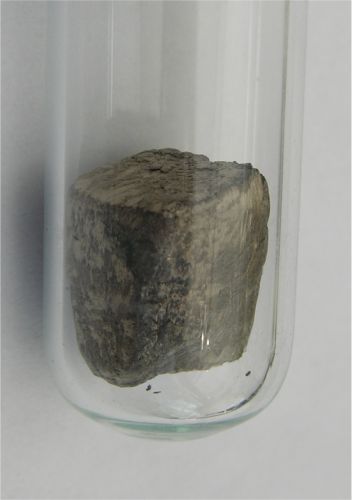

Cerium is a chemical element with the symbol Ce and atomic number 58. It is a member of the lanthanide series, a group of 15 metallic elements within the periodic table that are typically shiny, silver-white, soft metals, known for their high reactivity. Cerium is the most abundant of the rare earth elements, found in various minerals including cerite, monazite, and bastnasite, which are primary sources of commercial extraction. The element has distinctive properties, such as its ability to readily oxidize, and it plays a critical role in various industrial applications, including as a catalyst, in glass polishing, and in the manufacturing of alloys.

Historical Context

Cerium was discovered in 1803 by two Swedish chemists, Jöns Jacob Berzelius and Wilhelm Hisinger, and independently by the German chemist Martin Heinrich Klaproth. The discovery stemmed from their analysis of a new mineral, later named cerite, from which cerium gets its name. The simultaneous yet independent discovery by these scientists in different locations highlights the era’s burgeoning interest and advancements in mineralogy and chemistry. The early studies and characterization of cerium significantly contributed to the development of the periodic table and our understanding of the chemical behavior of elements, especially within the lanthanide series.

Properties and Characteristics of Cerium

Physical Properties

Cerium is known for its silvery, lustrous appearance, closely resembling iron in its physical characteristics. It is both ductile and malleable, allowing it to be stretched into wire or beaten into thin sheets without breaking. At room temperature, cerium remains in a solid state. The metal has a relatively low melting point compared to other transition metals, melting at about 798°C (1,468°F) and boiling at 3,442°C (6,228°F). These properties make cerium useful in various metallurgical applications, particularly in alloys.

Chemical Properties

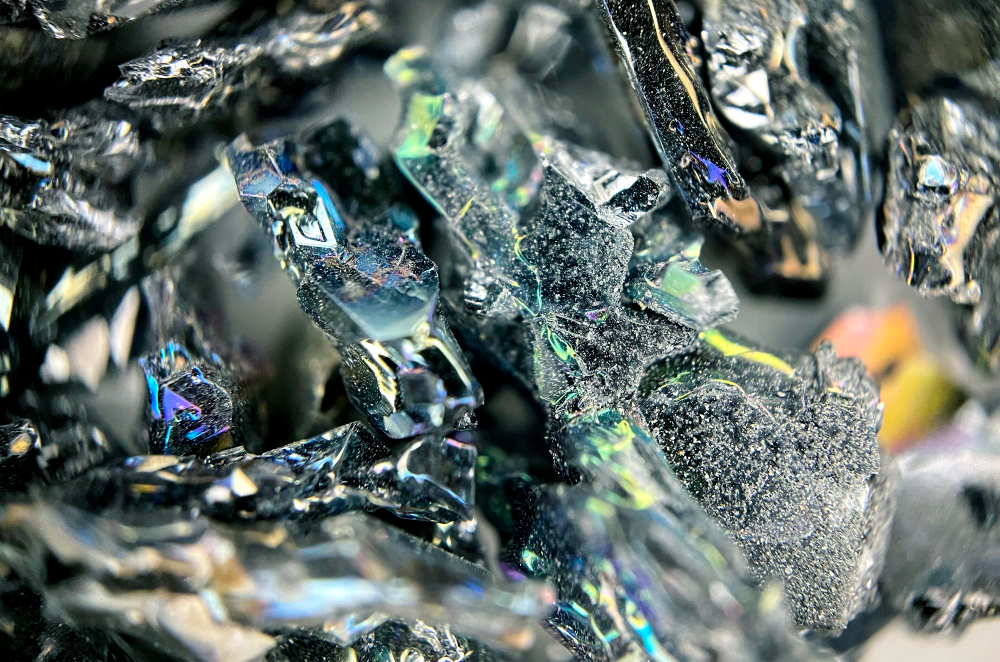

Chemically, cerium is quite reactive, especially when compared to more common metals such as iron or copper. It tarnishes when exposed to air and can oxidize rapidly, forming a spalling and loosely adherent oxide layer that peels off to reveal fresh metal. This behavior is indicative of its larger reactivity in the lanthanide series, primarily due to its variable oxidation states, Ce(III) and Ce(IV), with the latter being exceptionally stable. Cerium’s ability to rapidly oxidize is harnessed in various applications, such as in self-cleaning ovens, where it aids in the oxidation of food residues at high temperatures.

Isotopes

Naturally occurring cerium is composed of four stable isotopes: cerium-136, cerium-138, cerium-140, and cerium-142, with cerium-140 being the most abundant, accounting for about 88.48% of natural cerium. Apart from these stable isotopes, there are also synthetic, radioactive isotopes that have been identified, which are used in scientific research. These isotopes are produced either in nuclear reactors or particle accelerators and have applications ranging from tracers in geological research to studies in nuclear physics.

Occurrence and Production of Cerium

Abundance

Cerium is the most abundant of the rare earth elements and ranks as the 25th most abundant element in the Earth’s crust. Its prevalence is higher than many common metals like lead and tin, reflecting its widespread distribution in the earth’s mineral matrix. The element is primarily found in a variety of minerals, with the most significant being monazite and bastnasite, which contain a substantial percentage of rare earth elements, including cerium.

Mining Locations

The primary sources of cerium are found in several countries, each with significant deposits of cerium-bearing minerals:

- China: The largest producer of rare earth elements, including cerium, with heavy concentrations found in the Bayan Obo deposit in Inner Mongolia and the ion-adsorption clays in southern provinces like Jiangxi and Guangdong.

- United States: The Mountain Pass mine in California has been a significant source of rare earth minerals, including cerium, particularly bastnasite.

- Russia: Deposits in the Murmansk region, where loparite is mined, contain cerium among other rare earths.

- India: Monazite sands, rich in cerium, are mined extensively along the southern coasts, particularly in Kerala and Tamil Nadu.

- Australia: The Mount Weld mine in Western Australia is another notable location for extracting cerium through mining of monazite and bastnasite.

Extraction Process

The extraction and refining process of cerium from its ores involves several steps:

- Mining: The ore (commonly bastnasite or monazite) is extracted from open pits or underground mines.

- Crushing and Grinding: The raw ore is crushed and ground to liberate the minerals containing the rare earth elements.

- Physical and Chemical Concentration: Through processes like flotation and magnetic separation, the minerals are concentrated to increase the rare earth content in the material.

- Leaching: The concentrated ore is treated with acid (usually hydrochloric or sulfuric acid) to dissolve the rare earth elements, separating them from the ore matrix.

- Solvent Extraction: This stage involves the separation of cerium from other rare earth elements. It is conducted through a series of solvent extraction steps, where different reagents selectively bind to different rare earths based on their chemical properties.

- Precipitation and Calcination: Finally, cerium is precipitated out of the solution, typically as cerium oxalate, which is then calcined to convert it into cerium oxide.

This extensive process ensures the production of high-purity cerium, suitable for various industrial applications, reflecting its critical role in modern technologies and manufacturing processes

Applications of Cerium

Industrial Uses

- Automotive Catalysts: Cerium plays a crucial role in reducing vehicle emissions through its use in automotive catalysts. Cerium oxide is a key component in the catalytic converters found in exhaust systems, where it helps to convert harmful pollutants like nitrogen oxides, carbon monoxide, and hydrocarbons into less harmful substances such as nitrogen, carbon dioxide, and water vapor.

- Glass Polishing Powders: Due to its excellent chemical stability and hardness, cerium oxide is widely used as an abrasive in polishing powders for glass and mirrors. It is particularly valued for its ability to produce a high-quality finish without scratching the surface, making it essential in the manufacture of precision optical components.

- Alloying Material: Cerium is used as an alloying agent in various metals to improve their properties. For example, adding cerium to aluminum alloys enhances their heat resistance, while in iron and steels, it helps in refining grain sizes and improving workability and strength.

Technological Uses

- Fuel Cells: Cerium oxide, or ceria, is utilized in solid oxide fuel cells (SOFCs) due to its ability to conduct oxygen ions. This capability is critical for the efficient operation of fuel cells, which convert chemical energy from a fuel into electricity through a reaction with oxygen.

- UV Filters: Cerium oxides are effective at absorbing ultraviolet (UV) light, making them valuable components in the formulation of UV filters. These filters are widely used in plastics, cosmetics, and sunscreen products to protect against UV radiation.

Other Uses

- Self-Cleaning Ovens: In self-cleaning ovens, cerium is used due to its oxidation properties. It helps in the decomposition of food residues at high temperatures, facilitating the self-cleaning process.

- Carbon Arc Lighting: Cerium was historically significant in carbon arc lighting, particularly in the motion picture industry, where it was used to enhance the brightness and white light quality of arc lamps.

- Manufacturing of Colored Glasses: Cerium is also involved in the manufacture of colored glasses. It can be added to glass to both color it and provide UV protection. For example, it is used to create yellow-tinted glasses that filter out UV and blue light, enhancing contrast and reducing glare.

These varied applications highlight cerium’s versatility and its critical role in both everyday and advanced technological applications.

Economic and Environmental Impact of Cerium

Market Dynamics

- Global Demand and Supply Chain: The demand for cerium and other rare earth elements has increased significantly due to their indispensable role in high-tech applications, including electronics, renewable energy technologies, and automotive industries. The supply chain for cerium is highly concentrated, with China dominating both production and processing capacities. This concentration has led to geopolitical tensions and concerns over supply security, encouraging other countries to develop their own rare earth resources and processing facilities.

- Pricing Trends: The price of cerium fluctuates based on market demand, geopolitical influences, and production changes. Due to its abundance relative to other rare earths, cerium tends to be less expensive, but its price can still be volatile. Economic significance is profound, as fluctuations in cerium availability or price can impact various technology sectors, especially those manufacturing electronics and clean energy systems.

Environmental Concerns

- Impact of Mining: The extraction of cerium, like other rare earth elements, involves intensive mining operations that can lead to significant environmental degradation. These operations disrupt local ecosystems through deforestation, soil erosion, and contamination of water sources with hazardous chemicals used in the extraction process.

- Refining Processes: Refining cerium is chemically intensive, involving acids and solvents that can be harmful to the environment if not managed properly. The waste products from the refining process, which often contain low levels of radioactive materials and heavy metals, pose challenges in terms of treatment and disposal.

- Disposal and Recycling Challenges: Disposal of cerium-bearing products at the end of their life cycle is problematic. Recycling of cerium and other rare earth elements is not widely practiced due to the technical challenges and economic non-viability of the processes involved. This results in most end-of-life products being landfilled, leading to a loss of valuable resources and potential environmental harm from leaching materials.

The economic and environmental stakes associated with cerium highlight the need for sustainable mining practices, improved recycling technologies, and diversified global supply chains to mitigate environmental impacts and ensure economic stability in the markets dependent on this critical element.

.