Fibrolite is a term that can refer to two related but distinct things: a fibrous variety of a high‑temperature metamorphic mineral and a class of fiber‑reinforced cement products used in construction. Both meanings share themes of strength, heat resistance and fibrous texture, but they belong to very different contexts — one geological, the other industrial. This article explores where fibrolite occurs, how it is used, how to identify it, and several interesting facts and practical considerations that connect mineralogy, building technology and environmental concerns.

What fibrolite is: mineral and material definitions

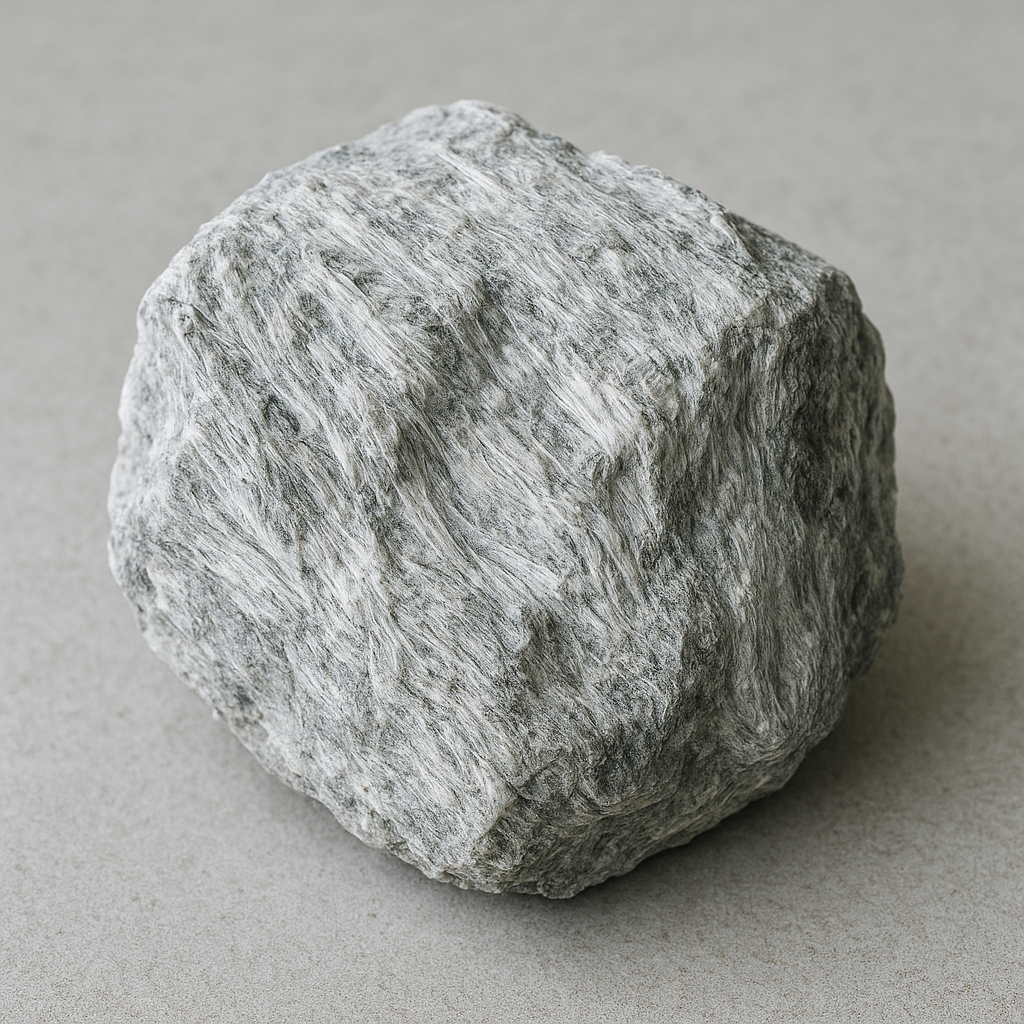

In mineralogical circles the name Fibrolite historically denotes a fibrous habit of the mineral sillimanite (chemical formula Al2SiO5). Sillimanite is one of the three aluminosilicate polymorphs (the others being kyanite and andalusite) that form under differing pressure‑temperature conditions during regional metamorphism. When sillimanite grows in slender, hairlike crystals it was traditionally called fibrolite because its texture resembles bundles of fibers. These silky fibres can produce striking optical effects under thin section and are useful to geologists as indicators of high‑temperature metamorphic conditions.

In engineering and construction contexts the name fibrolite (or fibrolit, fibrolite board) often refers to a class of fiber‑cement or cellulose‑fiber reinforced cement boards and sheets. These are manufactured by mixing cement with mineral or organic fibers, pressing and curing into panels used for roofing, cladding, partitioning and insulation. Historically similar products sometimes contained mineral fibers, and in certain periods and places asbestos was used in cement composites; modern formulations avoid asbestos and use safer fibers such as cellulose, glass or synthetic fibers.

Where fibrolite occurs: natural distribution and industrial geography

Natural occurrences

The fibrous variety of sillimanite forms in metamorphic rocks that experienced relatively high temperatures, typically during regional metamorphism associated with mountain building or contact with igneous intrusions. You can encounter fibrolite in well‑metamorphosed pelitic schists and gneisses, in skarns and in recrystallized sedimentary rocks that were subjected to high thermal gradients.

Known occurrences of sillimanite and fibrous sillimanite include metamorphic terranes worldwide: parts of the Himalayan belt (including Sri Lanka and India), Central and South America, North America (notably parts of the Appalachian belt), and segments of European shields where appropriate metamorphic conditions were met. Exact localities vary, and many metamorphic terrains host sillimanite either as prismatic crystals or fibrous aggregates, depending on pressure‑temperature history and rock composition.

Industrial and historical distribution

As an industrial product the use and distribution of fibrolite boards has been historically prominent in regions with active building markets and limited access to higher‑cost cladding materials. In Eastern Europe and parts of Asia, fiber‑cement sheets were widespread for roofing, fencing, and siding from the early 20th century through the mid to late 20th century. Brands and compositions varied by country and era, and small manufacturers often produced local variants under names like fibrolite, eternit, or cement board.

- Regions with large numbers of older buildings (Eastern Europe, parts of Latin America, and Africa) commonly show legacy installations.

- Modern fiber‑cement is produced globally by major building material companies and distributed through construction supply channels.

Applications and uses of fibrolite

Whether as a mineral or a constructed material, fibrolite is associated with properties that make it attractive for specific uses: thermal stability, mechanical strength in thin sections, and a fibrous texture that can be engineered or exploited.

Uses of fibrous sillimanite (mineral context)

- Geological indicator: As a stable high‑temperature polymorph, fibrolite helps geologists reconstruct metamorphic conditions and pressure‑temperature pathways in orogenic belts.

- Refractory and ceramic research: Aluminosilicate minerals such as sillimanite are studied for their high melting points and potential use as refractory aggregates in specialized ceramics and kiln linings (though more common commercial refractories use synthetic or other natural aluminosilicates).

- Collector specimens: The silky, radiating fibres of fibrolite can be visually attractive to mineral collectors and educational displays.

Uses of fibrolite boards and panels (industrial context)

Fiber‑cement boards historically served many building needs because they combined low cost, relative durability and fire resistance. Typical applications include:

- Roofing sheets for domestic and agricultural buildings.

- External cladding and soffits in low‑rise construction.

- Partition walls, ceilings and underlayment where moisture resistance and fire performance are desirable.

- Acoustic and thermal insulation layers within composite wall assemblies.

Modern fiber‑cement panels remain popular for façades and roofing, particularly when combined with contemporary design considerations. Their resistance to rot and flame and availability in large panels makes them useful for a variety of architectural solutions.

Properties, manufacturing and identification

Physical and chemical properties

In the mineral sense, fibrolite (fibrous sillimanite) exhibits the chemical composition characteristic of Al2SiO5, with a hardness around 6.5–7 on the Mohs scale and a specific gravity commonly between 3.2 and 3.3. Its fibrous habit produces a silky lustre and can yield a fibrous fracture. As a metamorphic mineral, it tells a story about the rock’s thermal history.

For the material product, key properties of fiber‑cement (fibrolite) panels include:

- Durability: good resistance to weathering and moderate mechanical loads.

- Fire resistance: non‑combustible matrix provides improved fire performance compared with many organic boards.

- Insulation: when combined with appropriate cavities or cores, panels contribute to thermal and acoustic insulation.

- Workability: panels can be cut, drilled and fixed with conventional tools (though dust control is necessary).

Manufacturing overview

Traditional fiber‑cement production involves mixing cement with fibrous reinforcement, water and sometimes mineral fillers, then pressing or extruding the composite into sheets which cure to gain strength. Modern processes (e.g., autoclaved fiber‑cement production) produce denser, more uniform boards with improved mechanical and dimensional stability. The choice of fiber influences behavior: cellulose fibers provide toughness and good bonding but may need protection from alkaline degradation; synthetic or mineral fibers improve long‑term stability and fire performance.

How to identify which fibrolite you are looking at

- If you are looking at a piece in bedrock with silky, radiating fibres and a crystalline appearance, you are likely looking at fibrous sillimanite — a mineralogical specimen.

- If you see flat panels, corrugated sheets, or manufactured boards used in roofing or cladding, you are dealing with a fiber‑cement product often called fibrolite.

- Texture, context and tools help identification: mineral fibrolite will show crystalline cleavage, high hardness and will be part of a rock matrix; manufactured fibrolite will have uniform thickness, fixing holes, painted surfaces or cut edges exposing the cement matrix.

Health, safety and environmental considerations

One of the most important practical topics related to fibrolite (in the construction sense) is the issue of asbestos. During much of the 20th century asbestos fibres were valued for their tensile strength and heat resistance and were sometimes mixed into cement products. In many countries the presence of asbestos in older fiber‑cement products has led to strict regulations on handling, removal and disposal, because inhalation of certain asbestos fibres is a proven health hazard.

- Never assume an old fibrolite sheet is asbestos‑free. Age, country of origin and manufacturer history influence risk.

- Testing for asbestos should be carried out by accredited laboratories; handling should follow local regulations and use licensed contractors for removal where required.

- Modern fiber‑cement products avoid asbestos and are engineered to minimize respirable dust during cutting and installation; appropriate PPE and wet cutting techniques reduce exposure.

From an environmental perspective, fiber‑cement panels have both positive and negative aspects. They can last many decades and resist rot, reducing material turnover, but cement production carries a significant carbon footprint. Recycling options exist but vary by locality and depend on whether the material contains hazardous components.

Maintenance, repair and safe handling

Working with fibrolite panels requires respect for their brittle nature and for dust control. Basic guidance includes:

- Use wet cutting or dust extraction when trimming panels to limit airborne particulate matter.

- For roof and cladding maintenance, ensure secure fastening and regular inspection for hairline cracks and edge erosion which can lead to water ingress.

- When replacing or disposing of old panels, consult local waste rules: asbestos‑containing materials are handled under special protocols; non‑asbestos panels may be amenable to recycling or recovery.

In geological fieldwork, collecting fibrous mineral specimens should likewise follow safety best practices to avoid inhaling fine dust when sampling or preparing specimens.

Interesting connections and lesser‑known facts

Fibrous minerals as metamorphic indicators

The fibrous habit of sillimanite (fibrolite) is more than an aesthetic curiosity — it is a crystallographic response to specific metamorphic stress and temperature regimes. Geologists use the presence of fibrous sillimanite to infer that the rock experienced relatively high temperatures, often associated with late‑orogenic heating or contact aureoles. Such details can refine tectonic reconstructions and mineral exploration strategies.

From asbestos to safer fibers

The evolution of fiber‑cement technology mirrors broader industrial transitions: as the health impacts of asbestos became incontrovertible, manufacturers reformulated products using safer substitutes — cellulose, wollastonite, polyvinyl alcohol fibers, and alkali‑resistant glass. This shift improved the safety profile of materials while prompting new research into long‑term performance and recycling strategies.

Architectural revival and contemporary design

Modern fiber‑cement panels have reappeared in contemporary architecture, prized for their clean lines, durability and ability to mimic other materials. Architects use them for ventilated façades, rainscreens and durable cladding that integrates with energy‑efficient wall systems. In this role fibrolite‑type products contribute to both aesthetics and building performance.

Alternatives and future trends

As construction moves toward decarbonization and circularity, alternatives to traditional cement‑heavy fibrolite emerge:

- Engineered timber and fiber‑reinforced polymers offer lower embodied carbon and high strength‑to‑weight ratios.

- Hybrid systems combine thin fiber‑cement outer skins with recycled insulating cores to reduce cement content.

- Lifecycle considerations encourage designs for disassembly and material recovery, which will influence the next generation of fibrolite‑style panels.

In mineral research, synthetic aluminosilicates and engineered ceramics continue to expand the applications once considered for natural sillimanite, particularly when precise compositions and performance are needed for high‑temperature technologies.

Practical resources and recommendations

- If you suspect a fibrolite board in an older building may contain asbestos, seek professional testing rather than attempting to sample it yourself.

- For builders considering fiber‑cement panels, specify modern, certified products and follow manufacturer guidance on installation and cutting to maintain warranties and safety.

- Collectors and students interested in mineral fibrolite should consult regional geological surveys and university departments for responsible field collection and sample preparation advice.

- When selecting building materials, weigh durability and fire resistance against embodied carbon and end‑of‑life options to meet sustainability objectives.

Fibrolite — whether admired as a silky, metamorphic mineral or used as a pragmatic building material — sits at an intersection of geology and human engineering. Its history touches on scientific discovery, industrial innovation, public health, and the changing priorities of construction practice. Understanding both meanings of the term helps professionals and enthusiasts make informed decisions about identification, use and stewardship of materials in the built and natural environment.