The Savage River Mine occupies a distinctive place in Australia’s mining landscape: a remote, industrial operation in the rugged northwest of Tasmania that produces high-quality magnetite concentrate for global steelmaking. More than just an orebody, Savage River is an integrated site that ties together geology, mining engineering, regional employment and complex logistics. The following article outlines where Savage River is located, the nature of the mineral product extracted there, the mine’s economic role, and several aspects that make it particularly interesting from technical, environmental and social perspectives.

Location and regional context

Savage River is situated in the northwest of Tasmania, on the rugged western side of the island state of Australia. The mine lies inland from the coastal towns that front Bass Strait, within a landscape of dense temperate rainforest, basaltic plateaus and steep river valleys. The nearest larger service centres are several hours’ drive to the east and north; historically the mine’s isolation has shaped both its logistics and its workforce arrangements.

The site takes its name from the Savage River that flows nearby. Its setting within Tasmania gives it some unique logistical challenges and also economic advantages: Tasmania is well placed to access Asian markets by sea, and the island’s smaller population means that large industrial projects have an outsized impact on local employment and infrastructure.

- Savage River mine is one of the few major iron operations in Tasmania.

- The nearest export infrastructure (shipping facilities and ports) is located on the north coast, requiring a well-managed transport chain.

- The area around the mine includes conservation reserves and sensitive ecosystems, increasing the emphasis on environmental management.

Geology and the product: what is mined and how it is processed

The Savage River deposit is primarily a magnetite iron ore body. Magnetite (Fe3O4) is an iron oxide that usually requires processing to create a high-grade concentrate suitable for efficient steelmaking. In contrast to typical hematite direct-shipping ores, magnetite is often mined and then concentrated on site through grinding and magnetic separation to produce a product with a higher iron content and lower impurities.

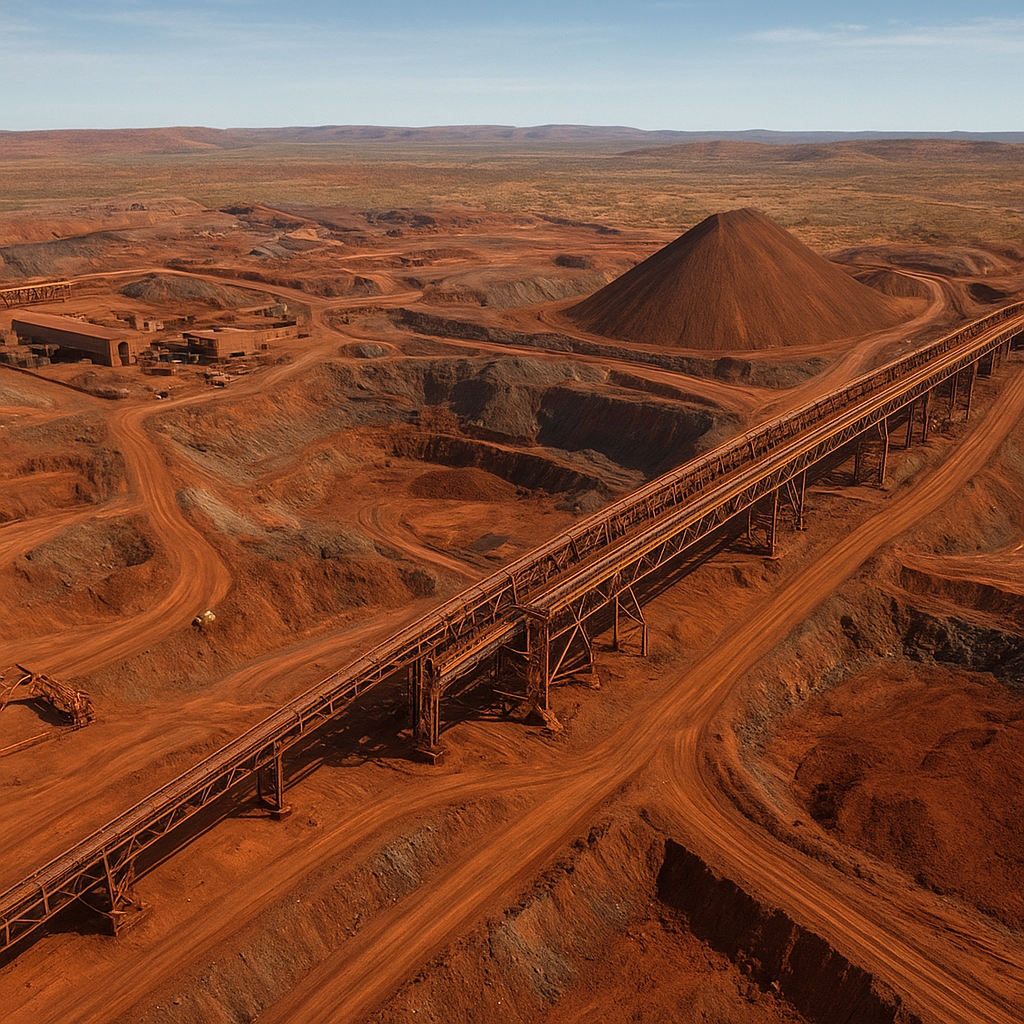

Mining at Savage River involves extracting ore from open pits, followed by comminution (crushing and grinding) and magnetic separation in a concentrator plant on site. The concentrate produced is a fine-grained, high-iron product suitable for blast furnaces or direct-reduction iron plants when blended appropriately. The concentration process reduces the mass that must be transported to port while increasing the iron content, which enhances the economic value of each tonne shipped.

Typical processing steps

- Drilling and blasting to break up the orebody in open-pit benches (open-pit mining).

- Primary crushing to reduce rock to manageable sizes.

- Grinding to liberate magnetite grains from the host rock.

- Magnetic separation to produce a high-grade concentrate.

- Filtration, drying and stockpiling prior to transportation to port.

The resulting concentrate has advantages for steelmakers: comparatively consistent chemistry, lower levels of deleterious elements and better suitability for metallurgical processes that demand feedstock of predictable quality. This makes Savage River concentrate particularly valuable in markets that emphasize quality and environmental performance of steelmaking feedstocks.

Operations, ownership and logistics

The mine is operated by a company that manages the extraction, processing and shipping chain. Over the years, ownership and operational details have evolved, but the site has remained an important source of magnetite concentrate for export markets. Because Tasmania is an island, the ore concentrate must be transported from the mine to an export port; this involves a carefully coordinated logistics chain combining road and port handling.

Transport typically consists of haulage from the concentrator to a coastal port facility where the concentrate is stockpiled and loaded on bulk carriers. Ports on Tasmania’s north coast handle the maritime leg to customers mainly in Asia. Logistics costs are a significant component of the delivered cost of ore, so operators at Savage River invest in efficient handling, road maintenance and port arrangements to remain competitive.

- Grange Resources is the operator responsible for the integrated mine and concentrate supply chain.

- Concentrate is moved from the mine to port via dedicated transport routes and port facilities.

- Operational flexibility allows the mine to adjust production volumes to world demand and pricing for iron products.

Economic importance

Savage River’s economic significance is multilayered. At the regional level, the mine is a major employer and a source of long-term local income. Small towns and service communities nearby rely on the mine’s payroll and procurement, and local contractors provide a wide range of services from road maintenance to catering and accommodation.

At the state and national level, the mine contributes to export earnings and supports the broader mining supply chain, including engineering, equipment manufacturing and shipping services. Iron ore products remain one of Australia’s key mineral exports, and high-grade magnetite concentrate from Savage River is a valued component of that export mix.

- Direct employment: the mine provides jobs in mining, processing, maintenance and administration.

- Indirect employment: contractors, transport providers and local businesses benefit from the mine’s activity.

- Fiscal contributions: royalties, taxes and business rates support public revenues and infrastructure.

- Export earnings: concentrate shipments generate foreign exchange and strengthen trade relationships.

Economic resilience is also a theme: because magnetite requires processing, operations at Savage River add value on site rather than simply shipping raw ore. This on-site beneficiation captures more economic value locally and contributes to regional industrial capability.

Environmental management and rehabilitation

Mining in a sensitive Tasmanian environment demands careful environmental management. Operators at Savage River must balance production with obligations to protect waterways, surrounding native vegetation and local biodiversity. Tailings management, water treatment, dust suppression and progressive rehabilitation are central components of environmental practice at modern mines.

Rehabilitation is particularly emphasized: as benches and waste dumps are completed, revegetation and reshaping reduce erosion and gradually return parts of the landscape to a more natural appearance. Monitoring programs track water quality, flora and fauna recovery, and the effectiveness of mitigation measures.

- Sustainability programs focus on reducing environmental footprint, managing tailings and ensuring long-term site stability.

- Water management includes capture, treatment and reuse of process water to minimize freshwater withdrawals.

- Native revegetation uses local seed sources where possible to encourage ecosystem recovery.

Community expectations in Tasmania for environmental stewardship are high; in response, the mine invests in continuous improvement of environmental controls and transparency through reporting and community consultation. The long-term closure plan for the mine includes detailed stages of rehabilitation and post-closure monitoring to ensure legacy issues are managed responsibly.

Community relations and social licence

The relationship between the mine and nearby communities is a critical part of ongoing operations. Local employment, procurement of local goods and services, infrastructure investments (for example, road improvements) and community sponsorships are typical ways the mine maintains a positive local footprint. Social licence to operate in a small-state context like Tasmania requires open dialogue and responsiveness to local concerns.

Key community-focused activities often include:

- Supporting local businesses through contract opportunities and procurement policies.

- Providing scholarships, training and apprenticeships to build local workforce capability.

- Funding community projects and contributing to local infrastructure upgrades.

These initiatives help align the mine’s operations with community expectations and establish long-term partnerships, which are essential for the mine’s continuity and reputation.

Challenges and opportunities

Like any mining operation, Savage River faces both operational challenges and strategic opportunities. Challenges include the remote location which increases logistical complexity, the need to maintain continuous environmental compliance in a sensitive landscape, and exposure to global commodity price fluctuations that affect profitability and investment decisions.

Opportunities include the increasing global demand for high-quality iron feedstocks as steelmakers pursue higher efficiency and lower emissions. High-grade magnetite concentrate can be more attractive to producers seeking to lower impurities in the steelmaking process. Additionally, evolving technologies in steel production — such as direct reduced iron (DRI) and the longer-term potential for hydrogen-based reduction processes — create demand patterns that could favor consistent, low-impurity magnetite concentrates.

- Operational optimization can reduce unit costs and improve environmental performance.

- Market diversification can reduce reliance on a single buyer or region.

- Technological advances in beneficiation could further improve concentrate quality and processing efficiency.

Interesting aspects and lesser-known facts

Savage River is interesting for several reasons beyond its commercial output. The mine operates in a landscape of high natural value, so integrating industrial activity with conservation goals has produced innovative environmental management practices. The concentrator model—turning an otherwise low-value ore into a premium concentrate—illustrates how on-site beneficiation can significantly alter the economic profile of a deposit.

Other notable points include:

- Remote workforce dynamics: The mine has developed logistical approaches to staff recruitment and retention suited to its isolated location, including rostered shifts and on-site accommodation.

- Integrated supply chain: Because concentrate shipping is a major cost component, the mine’s link to specialized port facilities and shipping schedules is tightly managed; this integration limits bottlenecks and helps maintain consistent delivery to customers.

- Focus on product quality: The magnetite concentrate is engineered to meet specific metallurgical specifications, making it more than a bulk commodity and allowing for premium pricing in some market conditions.

- Adaptive environmental practice: Progressive rehabilitation and community-focused conservation programs have been implemented to reduce long-term impacts and provide transparency for stakeholders.

The interplay of geology, metallurgy and logistics at Savage River makes it a compelling example of how a geographically isolated deposit can be transformed into a competitive, export-oriented operation by adding value at source and carefully managing the broader supply chain.

Future prospects and strategic relevance

Looking forward, Savage River’s future is tied to global steel demand, evolving technologies in iron and steel production, and the mine’s ability to sustain competitive operational costs while meeting environmental and social expectations. Growth in demand for higher-quality iron feedstocks—driven by stricter emissions standards and a push toward more efficient steelmaking—could favour operations that supply consistent, low-impurity concentrate.

At the same time, the mine’s continued success will depend on close engagement with local communities, investment in rehabilitation, and adaptive strategies to manage logistical and market risks. If these elements are successfully balanced, Savage River will remain an important contributor to Tasmania’s economy and an example of value-adding mineral processing in a challenging but potentially rewarding setting.