The Pilbara region in Western Australia is synonymous with giant open-pit mines, endless iron-rich landscapes and a logistics network that feeds the global steel industry. Stretching across a remote, sunbaked part of the continent, this area supplies a substantial share of the world’s seaborne iron ore, shapes national export figures and supports whole towns whose existence revolves around extraction and shipment. The following text explores where the Pilbara is located, what is mined there, the economic importance of those resources, and several striking or lesser-known facts that give the region its distinctive character.

Geography and geology: Where Pilbara sits in Australia

The Pilbara occupies the northwestern corner of Australia, within the state of WA (Western Australia). It encompasses an area of more than 500,000 square kilometres that ranges from rugged ranges and mesas to coastal flats and salt lakes. The geology of the Pilbara is ancient: much of the rock framework was formed over 2.5 billion years ago and includes the iron-rich banded iron formations (BIFs) that host the bulk of the mineralisation exploited by miners.

Key geological features

- Banded iron formations: These layered sediments are the primary source of high-grade, easily processed iron ore.

- Hamersley Range: A dominant geological province in the Pilbara where many of the biggest ore bodies are located.

- Coastal plains and ports: The proximity of deposits to the coast makes large-scale export by bulk carriers economically viable.

The Pilbara’s deposits are notable for containing extensive bodies of hematite and some magnetite. Hematite beds often occur as direct-shipping ore (DSO) that requires minimal processing beyond crushing and screening, which historically enabled rapid development and export growth.

What is mined: types of iron ore and major operations

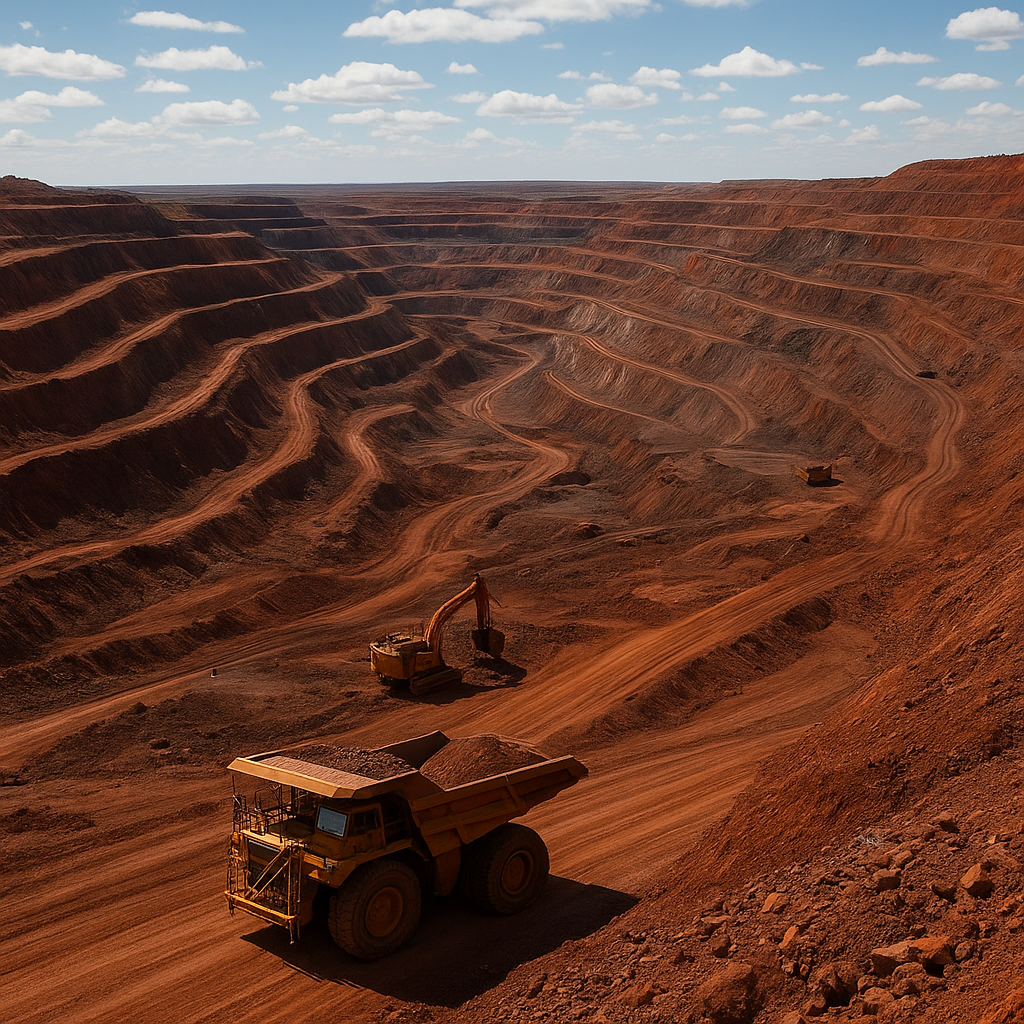

Iron ore is the unequivocal commodity of the Pilbara. Mining operations extract both high-grade hematite and lower-grade magnetite, the latter often processed in beneficiation plants to produce a saleable concentrate. The production methods are dominated by large-scale open-pit mining, intensive truck-and-shovel operations, and increasingly, automated systems for hauling and processing.

Major companies and mine complexes

- Rio Tinto — operates a cluster of mines across the Hamersley and Robe River areas, including world-famous pits such as Mount Whaleback and Tom Price-related operations.

- BHP — runs the Newman, Jimblebar and Yandi complexes, integrated with its southern export systems.

- Fortescue (FMG) — developed the Cloudbreak and Christmas Creek projects and expanded aggressively in the 2010s and 2020s.

- Roy Hill and other mid-tier projects — add to the region’s diversified production profile.

- Sino Iron (Cape Preston) — an example of magnetite processing in the region, producing concentrate rather than direct shipping hematite.

Open-pit mines in the Pilbara can be enormous. Mount Whaleback, developed by Rio Tinto, is often referenced as the largest single-pit open-cut iron ore mine in the world in terms of dimensions. Output from these operations is tailored for export: crude lumps and fines are sorted, sometimes beneficiated, blended to specification and then railed to dedicated port facilities.

Infrastructure and logistics: How ore reaches global markets

The success of the Pilbara as a global iron ore source depends not only on geology but on an extraordinary logistics system that links remote mines to the international marketplace. This system comprises heavy-duty railways, massive ship-loading terminals, and towns and services to sustain fly-in fly-out (FIFO) and residential workers.

Rail and port network

- Rail: Private heavy-haul railways that run hundreds of kilometres from mine sites to ports are a signature of the Pilbara. These lines are engineered for high axle loads and long, frequent trains. Automation has been introduced at scale, with some operators running autonomous train fleets.

- Ports: The principal export terminals are Port Hedland (the busiest bulk-export port in the region), Dampier, Cape Lambert and other satellite berths. Port Hedland alone handles hundreds of millions of tonnes annually during peak years.

- Ship types: Very Large Ore Carriers (VLOCs) and Capesize bulk carriers form the backbone of Pilbara exports, moving ore to steel-producing regions in East Asia, the Middle East and beyond.

Logistics also include massive stockyards, shiploader systems and blending facilities to meet the precise iron-content and impurity specifications of steelmakers. The coordination of rail schedules, shipments and maintenance is a complex operation that must run reliably to maintain contract commitments.

Economic significance: Local, national and global impacts

The Pilbara has an outsized economic role relative to its population. It is the primary source of Australia’s iron ore exports and a major contributor to national export receipts, employment and regional government revenues through royalties and taxes.

National value

- Export earnings: Iron ore exports from the Pilbara underpin a large portion of Australia’s export income and trade surplus during high-price periods.

- Investment and infrastructure: Investment in the region has financed some of Australia’s largest mining and rail projects, often with multi-billion-dollar capital outlays.

- Employment and services: Direct employment in mines and railways, plus secondary jobs in contracting, logistics, hospitality and government services, sustain regional towns and FIFO economies.

On the global stage, the Pilbara contributes a substantial share of the seaborne iron ore market. While global crude steel demand fluctuates with industrial cycles, Pilbara supply has the capacity to move prices and influence trade flows, given the scale and quality of many of its ores. The region’s proximity to major consumers in China, Japan, South Korea and other Asian markets is another strategic advantage.

Environmental and social dimensions

Large-scale mining inevitably raises environmental and social challenges. In a fragile landscape defined by unique ecosystems and Indigenous heritage, operators and regulators grapple with mitigating impacts and ensuring long-term stewardship.

Environmental considerations

- Land disturbance and rehabilitation: Open-pit mining dramatically alters landforms. Companies are required to present rehabilitation plans and progressively restore areas after mining.

- Water and dust management: Water is scarce in many parts of the Pilbara, so efficient water use, recycling and dust suppression are major operational priorities.

- Biodiversity: The Pilbara hosts endemic flora and fauna adapted to arid conditions; conserving habitats and managing invasive species are ongoing concerns.

Indigenous engagement and community

Many mining leases overlap areas of cultural significance for Aboriginal communities. Mining companies have legal and negotiated obligations to consult Traditional Owners, provide benefits through employment and procurement, and protect sacred sites. Several major agreements have been struck that include royalties, business opportunities and cultural heritage protections. Nonetheless, tensions and debates continue about land access, long-term cultural impacts and the equitable distribution of benefits.

Interesting facts and notable records

The Pilbara is more than a resource province; it is a place of technical firsts, striking natural features and historical depth. Below are some noteworthy items that illuminate the scale and uniqueness of the region.

- Pilbara rocks are among the oldest on Earth: parts of the area preserve geological records from the Archean eon, more than 2.5 billion years old.

- Port Hedland is one of the busiest bulk export ports in the world by tonnage, moving iron ore shipped from Pilbara mines across the globe.

- Autonomous rail technology: Operators developed and deployed some of the world’s first large-scale autonomous heavy-haul train systems to improve safety and efficiency.

- Massive ore trains: Trains running over 2 kilometres in length, hauled by multiple locomotives, are a common sight — an astonishing logistical achievement across remote terrain.

- Rapid scaling: Within decades of large-scale development, the Pilbara transitioned from sparse pastoral lands to a cornerstone of Australia’s mining export economy.

- Direct-shipping ore (DSO): The region’s high-grade hematite deposits provide ores that require little processing before being shipped — a factor that sped the internationalisation of Pilbara supply.

Challenges and future directions

Maintaining the region’s productivity and social licence requires adaptation. Companies and governments face pressures to decarbonise operations, reduce water use, support local economies beyond mining cycles and reconcile infrastructure expansions with community expectations.

Technological and market shifts

- Automation and electrification: Further automation of haulage and the electrification of mine sites and port systems can reduce greenhouse gas emissions and operating costs.

- Value-added processing: Some stakeholders advocate moving up the value chain — from raw ore exports to onshore processing or steelmaking — though economics and logistics make such moves complex.

- Market diversification: Demand from Asia has driven Pilbara exports for decades; diversification of markets and products can increase resilience to regional demand swings.

The Pilbara will likely remain central to global steel production for the foreseeable future, but the shape of its contribution can change. Efficiency improvements, evolving environmental standards and the potentials of new technologies will determine how mines operate, what sort of workforce is required and how revenue is generated and shared.

Places and names to remember

For those seeking quick orientation, a handful of places and entities define the Pilbara mining story:

- BHP, Rio Tinto and Fortescue — the major corporate names that dominate production and investment.

- Port Hedland, Dampier and Cape Lambert — the main export gateways to global steelmakers.

- Mount Whaleback, Newman, Cloudbreak, Jimblebar and Tom Price — representative mine sites and complexes.

- exports and global seaborne trade — the economic processes that turn Pilbara rock into steel in other countries.

Understanding the Pilbara involves both appreciating the scale of its geology and recognising the complex systems — technical, economic and social — that translate natural resources into exported value. Its story is one of ancient landscapes meeting 21st-century logistics and industry, with impacts that ripple across Australia and the wider world.