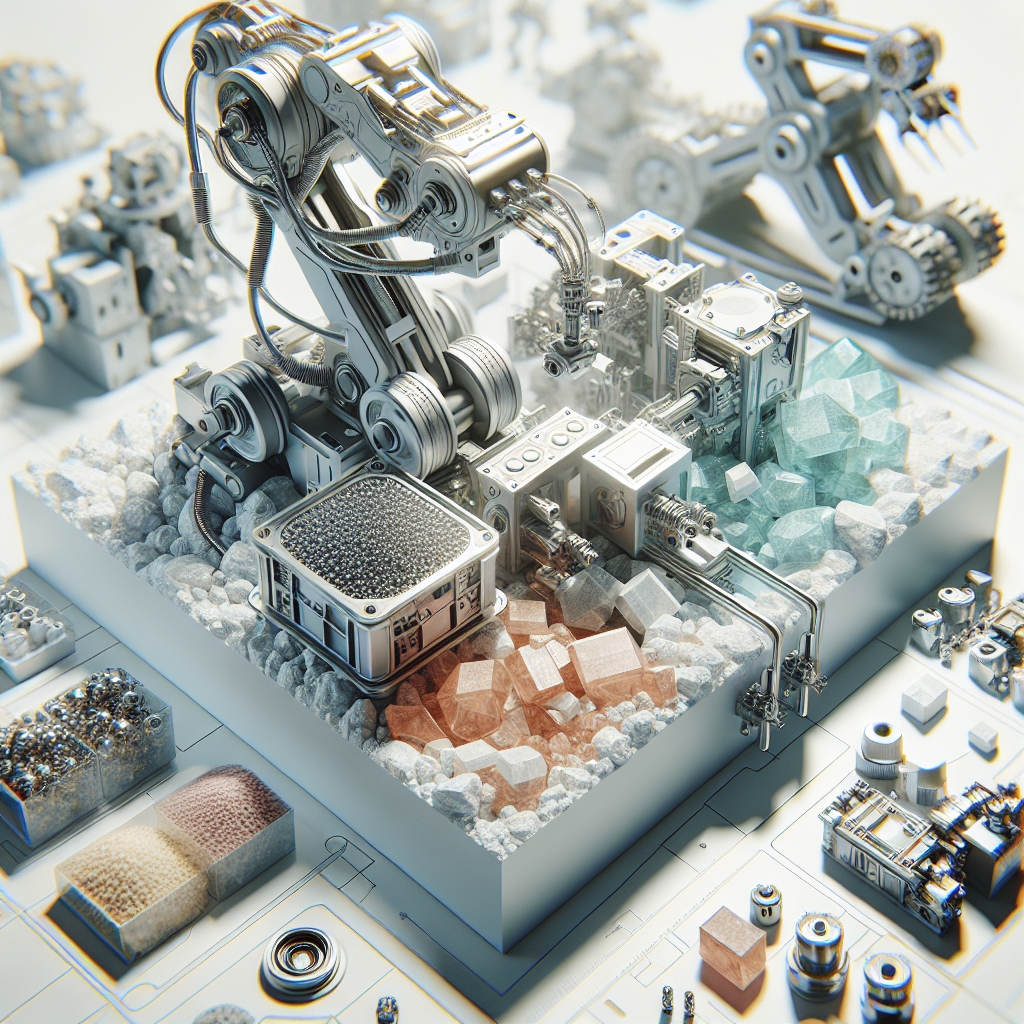

Rare earth minerals have become indispensable components in the burgeoning field of modern robotics and automation. These elements, often hidden in plain sight within the devices and technologies that define our contemporary lifestyle, are pivotal in pushing the boundaries of innovation and efficiency. This article delves into the role of rare earth minerals in robotics and automation, exploring their applications, challenges in sourcing and sustainability, and the future landscape of technological advancements powered by these critical resources.

The Critical Role of Rare Earth Minerals in Robotics and Automation

Rare earth minerals, a group of 17 elements found in the Earth’s crust, are essential for the manufacturing of a wide range of high-technology products. Among these, neodymium, dysprosium, and terbium stand out for their unique magnetic properties, which are crucial for the production of high-performance magnets used in various components of modern robotics and automation systems. These magnets are integral to the functionality of electric motors that power robotic arms, drones, and autonomous vehicles, offering superior performance in terms of efficiency, size, and weight compared to alternatives.

Beyond magnets, rare earth elements (REEs) are also vital in the production of batteries, sensors, and advanced electronics that form the backbone of modern automation systems. For instance, lanthanum is used in camera lenses, including those in robotic vision systems, due to its ability to refract light more effectively than other materials. Similarly, europium and terbium are used to produce the vibrant colors on digital displays, including those used in control panels for automated systems.

Challenges in Sourcing and Sustainability

Despite their name, rare earth minerals are relatively abundant in the Earth’s crust. However, their extraction and processing pose significant environmental and geopolitical challenges. The mining of REEs is often associated with substantial environmental degradation, including soil and water pollution, making it a subject of increasing concern. Moreover, the global supply chain of rare earth minerals is highly concentrated, with China dominating both the production and processing markets. This concentration raises concerns about supply security, especially for countries heavily invested in the development of high-tech industries, including robotics and automation.

The sustainability of rare earth minerals is another critical issue. The demand for these elements is expected to rise sharply as the world continues to advance in technology, particularly in green technologies such as electric vehicles and renewable energy systems, in addition to robotics and automation. This increasing demand puts pressure on existing resources and highlights the need for recycling and alternative materials. Recycling rare earth elements from electronic waste is a growing field of interest, but it currently represents only a small fraction of the supply. Research into alternative materials that can mimic or surpass the properties of rare earth minerals without the associated environmental and geopolitical issues is ongoing, but these solutions are still in their infancy.

The Future Landscape

The future of robotics and automation is inextricably linked to the availability and sustainability of rare earth minerals. As technologies continue to evolve, the demand for these critical materials is set to increase, underscoring the importance of addressing the challenges associated with their supply. Innovations in recycling and the development of alternative materials are promising avenues for reducing dependence on traditional sources of rare earth minerals. Additionally, geopolitical efforts to diversify the supply chain and reduce the concentration of production and processing capabilities are crucial for ensuring the stable growth of the robotics and automation sectors.

In conclusion, rare earth minerals play a pivotal role in the development and functionality of modern robotics and automation systems. Their unique properties enable the production of high-performance components essential for the advancement of these technologies. However, the challenges of sourcing and sustainability require concerted efforts from the global community to ensure that the future of robotics and automation is not only innovative and efficient but also sustainable and secure. As we move forward, the exploration of alternative materials, recycling technologies, and geopolitical strategies will be key in shaping the landscape of technology powered by rare earth minerals.